Shang Jianxuan, Chief Engineer of Shaanxi Coal Group: The high-quality development of coal chemical industry aims at the directional high-end transformation of low-rank coal

The report of the 20th National Congress of the Communist Party of China proposed that China will actively and steadily promote carbon peak and carbon neutrality, based on China's energy and resource endowment, adhere to the principle of establishing first and then breaking down, and implement the carbon peak action step by step in a planned manner; We will further promote the energy revolution, strengthen the clean and efficient use of coal, accelerate the planning and construction of a new energy system, and ensure energy security.

In recent years, Shaanxi Coal & Chemical Group (hereinafter referred to as Shaanxi Coal Group) has made a series of outstanding achievements in the clean and efficient utilization of coal, making important contributions to promoting the high-quality development of China's coal chemical industry and ensuring the independent supply of China's core strategic materials. In order to explore the road of scientific and technological innovation of Shaanxi Coal Group, recently, the reporter interviewed Shang Jianxuan, chief engineer of Shaanxi Coal Group, director of the National Energy Key Laboratory of Coal Quality and Clean Conversion, and director of the National and Local Joint Engineering Center for Green, Safe and Efficient Coal Mining.

Shang Jianxuan, Chief Engineer of Shaanxi Coal Group, Director of the National Energy Key Laboratory of Coal Quality and Clean Conversion, and Director of the National and Local Joint Engineering Center for Green, Safe and Efficient Coal Mining

Playing the role of "ballast stone" and realizing the utilization of coal quality is the core

China is a big country in coal resources. Coal accounts for 94% of the country's proven fossil energy resource reserves, which is the "ballast stone" and "stabilizer" of China's energy security. Statistics show that China's coal consumption accounts for about 56% of primary energy consumption, and the carbon emissions generated account for about 70% of energy consumption emissions (2021 data).

"Coal is an important bridge for China's green and low-carbon energy transition. For a long time to come, coal consumption will fluctuate within a safe range to support the development of new energy and the fluctuation of oil and gas. Under this situation, the clean and efficient use of coal will surely become an important foothold for China's energy transition. Shang Jianxuan told reporters that based on the actual situation of the coal chemical industry, it is imperative to explore a high-quality development path that is ecological priority and green and low-carbon in line with China's national conditions.

As the chief engineer of Shaanxi Coal Group, and also the director of the National Energy Key Laboratory of Coal Quality and Clean Conversion, and the director of the National and Local Joint Engineering Center for Green, Safe and Efficient Coal Mining, Shang Jianxuan has been presiding over and promoting the implementation of clean coal utilization in Shaanxi Coal Group. In the interview, Shang Jianxuan emphasized to reporters the importance of efficient utilization of low-rank coal resources. He said that China's coal industry should give full play to the attributes of coal as a dual carrier of energy and organic matter, and explore a clean and efficient transformation path with high efficiency, high-end products and low-carbon processes.

Shang Jianxuan said that China's low-rank coal resources are abundant, and with the westward shift of the main coal producing areas, the output of low-rank coal will be larger and larger in the future. However, at present, more than 90% of low-rank coal is directly burned for power generation, industrial boilers and domestic fuels, which has low resource utilization efficiency and high environmental protection costs.

Shang Jianxuan believes that the high-value components and chemical energy of raw coal can be used to the maximum extent of the high-value components and chemical energy of raw coal, which is a reasonable direction for coal chemical industry. Over the years, he has led the technical team of Shaanxi Coal Group to develop a series of green and efficient quality conversion and utilization engineering technologies with low energy consumption and low carbon emissions based on the industrial composition and organic matter structure of low-rank coal.

Talking about the core idea of "quality utilization", Shang Jianxuan said that the quality utilization of low-rank coal refers to the cross-link bond fracture and product reorganization between the large and small structural units of low-rank coal through medium and low temperature pyrolysis, and the first quality is converted into gas (pyrolysis gas), liquid (coal tar), solid (semi-coke) three forms, and then the pyrolysis gas, coal tar, and semi-coke are further converted and utilized, so as to obtain coal-based special fuels, high-end process oil products, scarce chemical raw materials and hydrogen, methane, heat and electricity clean energy economically and environmentally friendly.

"Compared with combustion, gasification, liquefaction and other processes, the reaction conditions of low-rank coal quality utilization technology are mild and the energy consumption is low; The conversion and utilization efficiency of carbon, hydroxide and oxygen elements is high, and the carbon emission is low; The structural units of coal are not excessively split, and the liquid products are mainly naphthenes. Most of the impurities such as sulfur and nitrogen enter the gas part, which is conducive to resource recycling; The recovery of water in the drying section of coal, with low water consumption and less sewage generation, is an important path for the clean and efficient utilization of coal with low energy consumption, low carbon emission and low material consumption. Shang Jianxuan said.

In recent years, the utilization of low-rank coal has risen to a national strategic demand. The state has successively issued a number of plans and action plans involving the utilization of coal quality. "At present, China has planned and laid out four modern coal chemical industry demonstration zones in Yulin, Shaanxi, and Zhundong, Xinjiang, and steadily promoted the construction of kerosene and gas strategic bases such as Yulin in Shaanxi and Ordos in Inner Mongolia, established production capacity and technical reserves, encouraged the research and development and demonstration of low-rank coal technology, promoted the grading and quality improvement of low-rank coal origins, and focused on key technologies such as pulverized coal pyrolysis, tar quality conversion, and semi-coke utilization, and promoted the cascade utilization of coal quality classification." Shang Jianxuan told reporters.

The picture shows Shang Jianxuan (first from left) conducting experimental guidance at the National Energy Key Laboratory of Coal Quality and Clean Conversion

Concentrate on the road of independent research and development, and open up the high-efficiency pyrolysis channel of low-rank coal

Shaanxi Coal Group is a state-owned super-large energy and chemical enterprise in the western region of China, and after 19 years of reform and development, it has grown into a backbone energy and chemical enterprise in Shaanxi and even the whole country. Shang Jianxuan said that Shaanxi Coal Group, based on the abundant reserves of low-rank coal resources in northern Shaanxi, systematically put forward the concept of low-rank coal quality and clean conversion and polygeneration utilization at the beginning of its establishment.

Over the years, Shaanxi Coal Group has established a low-rank coal quality clean and efficient conversion technology development system, successively built a number of scientific research platforms, and with the support of "enterprise-based combination of production, education and research", carried out a large number of key core technology research, steadily promoted engineering development in stages and steps, built a number of industrial demonstration projects, and achieved a series of scientific and technological achievements.

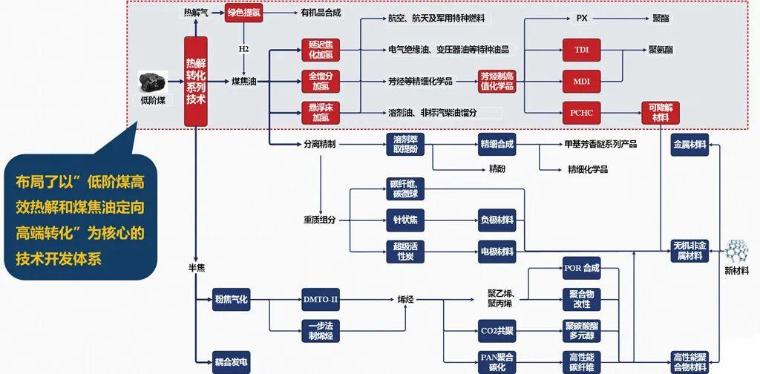

Among these achievements, it is particularly worth mentioning the layout of the technology development system with "high-efficiency pyrolysis of low-rank coal and directional high-end conversion of coal tar" as the core (as shown in the figure below).

In this core system, how to carry out efficient pyrolysis of low-rank coal is a key point that needs to be broken through. Shang Jianxuan told reporters that in recent years, Shaanxi Coal Group has independently developed a series of graded and efficient pyrolysis technologies suitable for different particle sizes in order to achieve "moderate molecular cutting and directional transformation of structural units" of low-rank coal, and has achieved a major breakthrough in key technological innovation.

According to reports, for lump coal, Shaanxi Coal Group has developed a new type of internal heating vertical furnace pyrolysis technology (SM-DXY). This technology realizes clean and efficient pyrolysis with wide particle size, reduces the comprehensive energy consumption per unit product by more than 30%, and reduces the output of wastewater by more than 50%. At present, this technology has entered the stage of large-scale commercial operation.

For granular coal, the Group has developed a regenerative hydrogen-rich gas heat carrier pyrolysis technology (SM-GF), which solves the problems of poor air permeability and low heat exchange efficiency of granular coal. Compared with the traditional process, the effective components in the gas are increased by 85%, the consumption of coal water per ton is reduced by 70%, and the energy consumption is reduced by 25%.

In addition, the Group has also developed a low-rank coal rotary pyrolysis technology (SM-TY) for the pyrolysis of granular coal. The technology has successively overcome a series of problems such as equipment amplification, pipeline blockage, high dust content in oil and gas, short operation cycle, equipment coking, oil-water separation, etc., and passed the technical appraisal of China Petroleum and Chemical Industry Federation in 2019. Nine academicians and experts of the Chinese Academy of Sciences, including Xie Kechang, Ni Weidou, Yang Qiye and Li Hongzhong, who participated in the appraisal, agreed that the overall level of the technology has reached the international leading level.

For pulverized coal, the group company has developed a low-order pulverized gas solid heat carrier dual-cycle rapid pyrolysis technology (SM-SP), and built the world's first "1.2 million tons/year pulverized coal rapid pyrolysis demonstration project" in 2022. Shang Jianxuan said that the technology has broken through major problems such as the scale expansion of the device, the improvement of tar yield, and the online separation of high-temperature oil, dust and gas, with an average tar yield of 17.53%, which is 1.5 times the theoretical value of Gejin test, and has realized large-scale, rapid and efficient pyrolysis of low-rank coal.

In addition, Shaanxi Coal Group has also developed a conveyor-bed pulverized coal rapid pyrolysis technology for pulverized coal pyrolysis. The coupling of this technology with coal-fired power generation can effectively promote the value enhancement of the coal and power generation industry chain, and promote the clean and efficient use of coal and the transformation and upgrading of traditional coal power. At present, the technology has completed the 10,000-ton industrial test, and the development of a million-ton process package is being carried out.

Shang Jianxuan revealed that at present, Shaanxi Coal Group has achieved a lump coal pyrolysis capacity of 10 million tons/year, a granular coal pyrolysis capacity of 1.1 million tons/year, and a pulverized coal pyrolysis capacity of 1.2 million tons/year.

The picture shows Shang Jianxuan (third from right) accompanying Academician Peng Suping (third from left) and industry experts to inspect two major national demonstration projects of 1.2 million tons of pulverized coal pyrolysis per year and 500,000 tons of coal tar to special oil products per year

Aiming at "directional high-end transformation", we will realize the independent production of core materials

At present, there are still blank areas in the independent production of key core materials in China. Shang Jianxuan led the technical team of Shaanxi Coal Group to independently develop a series of breakthrough technologies aimed at the "directional high-end transformation" of low-rank coal, filling a number of domestic gaps.

Coal tar is the main product in the pyrolysis process of low-rank coal, and Shang Jianxuan said that the efficient use of coal tar is the key point to realize the efficient and clean utilization of low-rank coal. In recent years, Shaanxi Coal Group has built 3 hydrogenation and 1 separation and refining routes for low-temperature coal tar in pyrolysis products, making new major breakthroughs in green production and realizing high value-added leaps in products.

The reporter learned that at present, the oil processing capacity of Shaanxi Coal Group has reached 2.67 million tons/year, including many special products with high added value. "In terms of improving the added value of products, Shaanxi Coal Group has developed a complete set of industrialization technology (SM-FU) for the hydrogenation of medium and low temperature coal tar full fraction to naphthenic special oil products, and the products produced by this technology have been applied to aerospace, special military and other fields, and truly realize the high-end transformation of coal." Shang Jianxuan said that this technical system has built a series of products of 10 categories and 23 series of products based on high-end coal tar for the first time, and has taken the lead in realizing the production of coal-based aerospace kerosene, military diesel, high flash point jet fuel, large specific gravity jet fuel and other special oil products from medium and low temperature coal tar, and the performance indicators of the whole series of products have met or exceeded the requirements of the corresponding national standard/military standard.

Using this technology, Shaanxi Coal Group has built the world's first "500,000 tons/year coal tar to naphthenic oil demonstration project", and the tar-based aviation kerosene produced has completed two long-range test runs of high-thrust rocket engines, both of which have been complete successes. The data show that the aerospace kerosene has the characteristics of high specific impulse, superior heat transfer performance and coking performance. It has obtained the national weapons and equipment quality management system certification, passed the application review of a new generation of launch vehicles, and opened up a new path for coal-based aerospace and military special fuels.

In addition, Shaanxi Coal Group has also developed technologies for producing aromatics and high-density fuels from coal tar; It has independently developed a series of catalysts such as high-efficiency hydrogenation and condensation reduction of precious metal hydrogen, which has overcome the problem of conversion of heavy components of coal tar and provided strong technical support for the diversification of raw materials for aromatic hydrocarbon production in China.

In addition to making breakthroughs in key technologies, Shang Jianxuan also focused on the problem of "chain". The deployment of the innovation chain around the industrial chain is another key task for him to lead the group's technical team to promote the implementation. Shang Jianxuan said that Shaanxi Coal Group has formed a low-rank coal quality conversion system based on the principles of "recycling of materials" and "cascade utilization of energy". While tackling the core technologies of high-efficiency pyrolysis and tar directional conversion, through multidisciplinary and cross-field integration and innovation in mining, chemical industry, thermal energy, environment and other fields, we have successively developed high-value and high-end extension technologies for product chains such as low-rank coal pyrolysis-semi-coke gasification/power generation integration, polyolefin elastomers, and high-strength and high-modulus carbon fibers.

"The group has developed key technologies such as the integration of pyrolysis and gasification of low-rank coal, semi-coke power generation, hydrogen production from coal gas, aromatics from coal tar and fine chemicals, utilization of waste heat and residual gas, recycling of pollutants, utilization of mine water and ecological reconstruction, etc., forming a whole industry chain technology system with the core of low-rank coal quality transformation." Shang Jianxuan said.

In the interview, we learned that relying on the technical system of the whole industry chain, Shaanxi Coal Group has developed a series of high-value and high-end extension projects of the product chain. These projects have broken the monopoly of foreign technology and realized the independent production of a number of core strategic materials. For example, the 30,000 tons/year polyolefin elastomer project has realized the subversive replacement of traditional ethylene propylene rubber and broken the monopoly of foreign technology; The 5,000 tons/year diphenylmethane diisocyanate (MDI, TDI) project adopts the green synthesis technology of non-phosgene route to replace the original high-toxicity and high-pollution phosgene process, greatly reduce the dependence of products on foreign countries, and realize localized substitution; The 1,000 tons/year super activated carbon project is expected to break the foreign dependence of domestic super activated carbon for supercapacitors; The 100-ton T1100 carbon fiber project has developed a new generation of ultra-high-strength carbon fiber products with a strength of 7000MPa and a modulus of 324GPa, realizing the localization of core materials.

Shang Jianxuan (second from right) guides the work at the production site of the million-ton pyrolysis plant

The transformation of coal chemical industry is not waiting for me, and the utilization of low-rank coal is promising

"The coal chemical industry has great potential and great prospects, and it is necessary to improve the comprehensive utilization efficiency of coal as a chemical raw material, promote the high-end, diversified and low-carbon development of the coal chemical industry, take strengthening scientific and technological innovation as the most urgent task, accelerate the research of key core technologies, and actively develop coal-based special fuels, coal-based biodegradable materials and other products." At the end of the interview, Shang Jianxuan made such a summary and outlook on the development of China's coal chemical industry.

Talking about the development prospect of low-rank coal quality utilization, he provided reporters with such a set of data:

If 200 million ~ 400 million tons of low-rank coal (10%~20% of the output of low-rank coal) are converted on site, at least about 20 million ~ 40 million tons of medium and low temperature coal tar can be produced. Through the coal tar directional conversion technology, at least 10 million ~ 20 million tons of special military and aerospace fuels and 10 million ~ 20 million tons of high-performance process oil and cyclohexane fine chemicals can be produced.

If 1 billion tons of raw coal are converted locally in the western mining area, 150 million tons of oil energy can be produced, which can reduce China's dependence on crude oil from 71.2% to about 50.2% (2022 data); At the same time, it will provide 60 million tons of basic chemical raw materials to the market to alleviate the consumption of petroleum by chemical raw materials; Nearly 500 million tons of clean semi-coke were provided to power generation, chemical industry and civil use to reduce the pressure on downstream environmental protection.

It can be seen that promoting the utilization of low-rank coal is of great significance for China to achieve the green transformation of energy and steadily achieve the strategic goal of "double carbon". In addition, the low-rank coal quality utilization route has low water consumption and high energy conversion efficiency, which is also an important path to promote the high-quality economic and social development of the coal-rich and water-scarce areas in Northwest China.

It is time to promote the transformation of the coal chemical industry to green and high-end. Shang Jianxuan called for the clean and efficient use of coal as a new national energy technology. "It is recommended that basic research and cutting-edge technologies be incorporated into the national laboratory research system, support the development of forward-looking, pioneering and 'stuck' major technologies and equipment research, and give support policies for the industrialization demonstration of clean and efficient utilization of coal quality." He said.

In addition, Shang Jianxuan also put forward development suggestions such as "considering the particularity of the coal-to-liquid industry, reducing or exempting the consumption tax on coal-to-liquids as appropriate" and "encouraging the clean and efficient conversion of coal and the coordinated coupling development of new energy, power and other industries".

Shang Jianxuan introduced that in the next step, Shaanxi Coal Group will use the developed advanced technology to comprehensively upgrade the Yulin blue carbon industry, establish a new chemical system with medium and low temperature coal tar and pyrolysis gas as the main raw materials, and promote the "replacement of commercial coal" by clean semi-coke. At the same time, based on the advantages of resources and technology and industrial foundation, Shaanxi Coal Group plans to build large-scale low-rank coal quality utilization bases in Yulin, Shaanxi, Ordos, Inner Mongolia, Tuha, Xinjiang and other places, and build a resource development, technical standards and industrial development system for low-rank coal quality utilization.

"Coal-based, energy and materials go hand in hand, technology and finance dual drive, zero-carbon transformation, and determined to become a world-class enterprise" is not only the development vision of Shaanxi Coal Group, but also the important responsibility of Shang Jianxuan as the technical coach of the group. In recent years, the international situation is complicated, and it is precisely because of the existence of experts like Shang Jianxuan who are dedicated to independent innovation and tirelessly seeking scientific and technological progress that China's energy and chemical industry can continue to cross one scientific research peak after another, break through one scientific and technological barrier after another, and stand firm in the position of a major country and achieve rapid development in the increasingly fierce international competition.