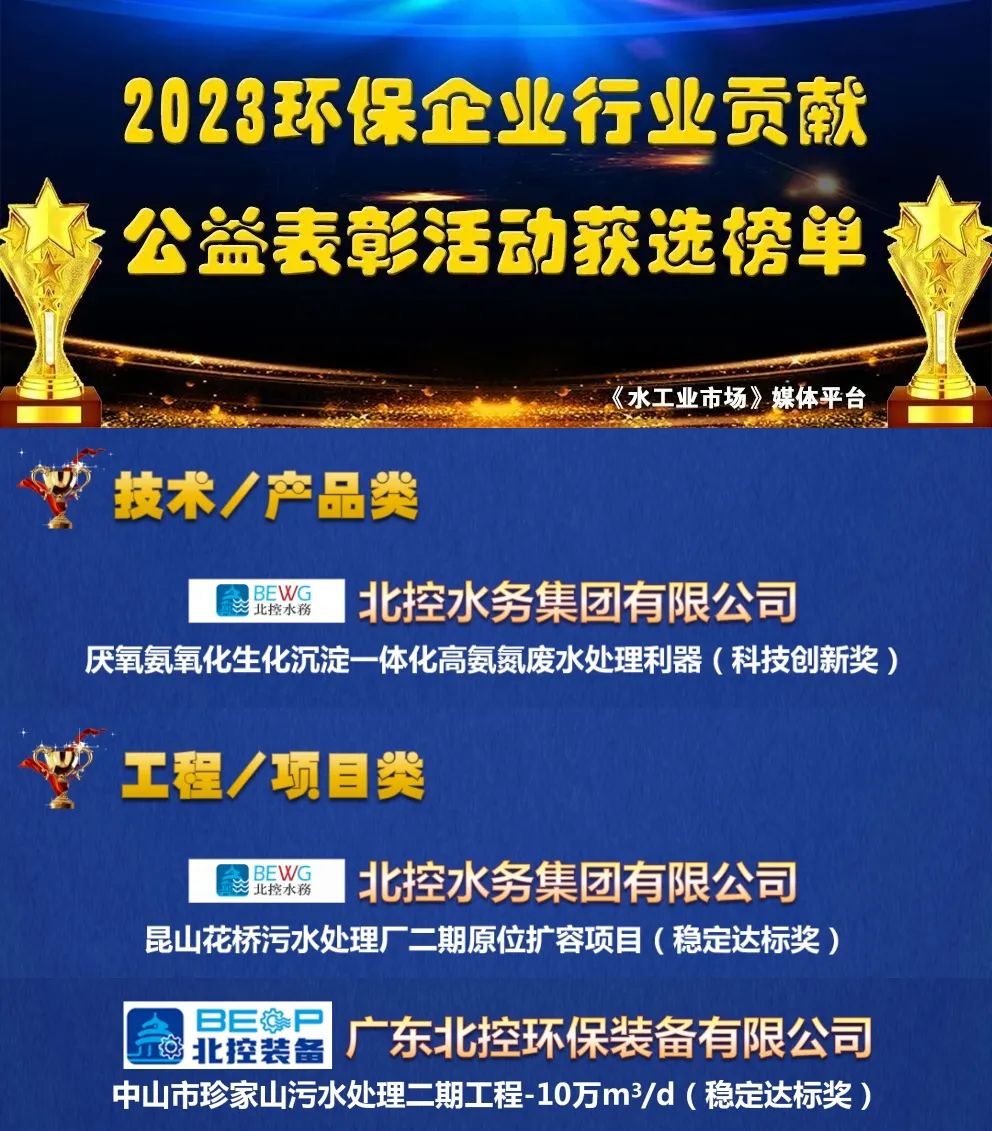

BEWG won two awards in the 2023 Environmental Protection Enterprise Industry Contribution Public Welfare Commendation Activity

On January 2, the list of 2023 Environmental Protection Enterprise Industry Contribution Public Welfare Commendation Activities was officially announced, and BEWG won the Science and Technology Innovation Award for "Anaerobic Ammonia Oxidation Biochemical Precipitation Integrated High Ammonia Nitrogen Wastewater Treatment Weapon", and the "Kunshan Huaqiao Sewage Treatment Plant Phase II In-situ Expansion Project" and "Zhongshan Zhenjiashan Sewage Treatment Phase II Project - 100,000 m³/d" won the Stability Compliance Award.

Launched in 2010 by the media platform "Water Industry Market", the public welfare commendation activity for the contribution of environmental protection enterprises aims to take stock and summarize the changing path of the development of China's environmental protection industry, and record and commend outstanding enterprises in the environmental protection industry that create value. After winning the Innovation Breakthrough Award and the Green and Low-Carbon Award in 2022, BEWG once again expanded the award track. This award is an important embodiment of BEWG's technological innovation, demonstrating BEWG's strong scientific and technological innovation strength and efficient operation and service capabilities.

Science and Technology Innovation Award - Anaerobic ammonia oxidation and biochemical precipitation integrated high ammonia nitrogen wastewater treatment tool

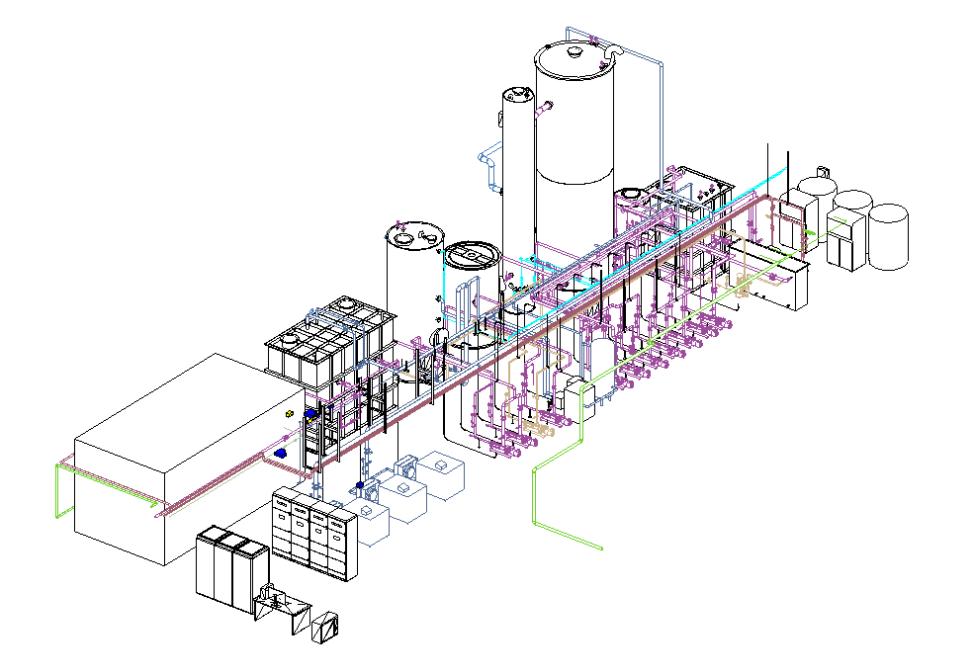

Based on the anaerobic ammonia oxidation biochemical precipitation integrated high ammonia nitrogen wastewater treatment technology of BEWG, BEWG has independently developed a new technology for intelligent high ammonia nitrogen wastewater treatment based on the anaerobic ammonia oxidation bacteria of granular sludge structure and the one-stage biochemical reaction process, breaking through the bottleneck of one-stage anaerobic ammonia oxidation technology, combined with the automatic regulation and control of water and gas distribution in the core process unit, to realize the intelligent control of the reaction process, the efficiency of pollutant removal capacity, and the stabilization of the operation effect of the process system. The R&D process of technical products lasted five years, and a complete technology R&D and application chain from laboratory research to production verification engineering was successfully established. He has applied for and authorized 4 patents and published 5 high-level academic papers.

The technology is efficient and low consumption, the ammonia removal rate can reach 90%~95%, the total nitrogen removal rate can reach 80%~85%, and the aeration energy consumption is 55%~60% of the traditional process. Saving land area, the one-stage short-path nitrification-anaerobic ammonia oxidation process carries out short-range nitrification and anaerobic ammonia oxidation in the same reactor at the same time, which saves 80% of the floor area and reduces the construction cost of the structure compared with the traditional nitrification and denitrification process and the two-stage short-range nitrification-anaerobic ammonia oxidation process. Green and low-carbon, no need to invest in carbon sources, reduce greenhouse gas emissions by 90%, and reduce sludge production by 90%.

In terms of intelligent control, the module design is realized, the core operating parameters are programmed with control strategies, and intelligent real-time optimization and control is adopted, and the core hardware equipment and reaction units are skid-mounted design, modular assembly, high integration, and fast project implementation. BEWG anaerobic ammonia oxidation technology has been effectively verified, and the production verification project has been carried out in the Kunming food waste treatment project, through BIM design and prefabricated skid-mounted construction, the process system of "pretreatment + high-load decarburization + anaerobic ammonia oxidation" is adopted, and the treatment object is kitchen biogas slurry wastewater (high ammonia nitrogen + high organic matter), with a treatment scale of 30~50m³/d. The project team scientifically formulated the control strategy, reasonably set the control parameters, and continuously iterated the automatic control program, and the verification project has achieved stable operation for 6 months.

Stability Achievement Award - Kunshan Huaqiao Sewage Treatment Plant Phase II In-situ Expansion Project

The second phase of the in-situ expansion project of Kunshan Huaqiao Sewage Treatment Plant is located in Huaqiao Economic Development Zone, Kunshan City, Jiangsu Province, with a designed treatment capacity of 62,500 tons/day and a total investment of about 136 million yuan, which has been completed and put into operation in August 2022. Using the treatment process of "aeration and sedimentation integrated tank" + "magnetic coagulation sedimentation tank" of the Kuoneng ® series products of BEWG, no new land has been added in the second phase of the project, and the scale has been doubled through in-situ expansion technology. The effluent of the project has stably reached the standard of Table 2 of the "Discharge Limits of Major Water Pollutants from Urban Sewage Treatment Plants and Key Industrial Industries in Taihu Lake Area", and has reached the "Suzhou Special Discharge Limit Standards" through management improvement. This project has been selected into the "14th Five-Year Plan" Ecological Environment Innovation Project Case Collection by China Environment News.

The technology is advanced and the emission standard is high. The main body of the project adopts the new process of aeration and sedimentation integrated tank, which has a variety of functions such as denitrification and phosphorus removal, nitrification and carbon reduction, precipitation and separation, etc., and has the advantages of land saving, capacity expansion and efficiency, plug and play, and system improvement.

Stacked layout, extreme land. Under the background of extremely tight land use, the project adopts the process of intensive aeration and sedimentation integrated tank, and through the combination and division of multiple process sections plane and vertical, the ultimate layout without new land is realized under the condition of doubling the in-situ expansion of water volume, and the project occupies more than 50% of the land area compared with conventional projects, and the whole process saves 0.7~1.0m2/(t/d) per ton of water.

Reduce energy consumption and save costs. Based on the actual characteristics of the project, the vertical gravity flow direction is adopted, and the overall level is upgraded, the aeration and sedimentation integrated tank is set up in the biochemical part to improve the efficiency of the biochemical reaction, the deodorization system is partially reused and deodorized in the vicinity, and the energy consumption, investment cost and operating cost of the system are greatly reduced.

Data empowerment, intelligent operation. This project is equipped with the BECloudTM smart water operation and management platform independently developed by BEWG, which optimizes and accurately regulates the project in real time based on the big data of BEWG operation, and monitors the operation status and data of the equipment in real time, and transmits it to the operation database for feedback and iteration, so as to realize intelligent and digital operation services.

Create a benchmark and lead by example. The project has a high standard of effluent, and the tail water is used for ecological water replenishment, which is discharged into the Wusong River through the Xiaowapu River, which improves the ecological environment of the downstream city, and the in-situ expansion and transformation of the project releases 45 acres of land use index, alleviating the pressure of regional land tension. The application of BEWG Kuoneng ® aeration and sedimentation integrated tank products solves the problem of overload operation of water plants, prepares for the long-term development of local water volume growth, and also creates a benchmark model for the in-situ expansion of sewage plants.

Stability Standard Award - Zhongshan Zhenjiashan Sewage Treatment Phase II Project- 100,000m³/d

The second phase of Zhongshan Zhenjiashan Sewage Treatment Plant is located in Torch Development Zone, Zhongshan City, Guangdong Province, with a design scale of 100,000 m³/d, and adopts the core treatment process of "AOA biochemical tank + external medium high-efficiency sedimentation tank". The total investment of the project is about 350 million yuan, which is about 15% less than the traditional AAO solution, and the construction period is about 8 months, which is more than 4 months compared with the traditional AAO solution. The project started construction in February 2022 and was connected to water in October of the same year. The effluent stably reaches the stricter value in the first class A discharge standard of the national "Pollutant Discharge Standard for Urban Sewage Treatment Plants" (GB18918-2002) and the first level standard of the second period of the local standard "Water Pollution Discharge Limit" (DB44/26-2001) of Guangdong Province.

Extreme nitrogen removal, efficient and land-saving. The denitrification efficiency of AOA process is 30% higher than that of A2/O process, and the effluent index is stably better than that of the national standard first-class A standard, and the retention time is reduced while strengthening denitrification and phosphorus removal, and the corresponding pond capacity, land occupation and civil engineering investment are saved by 20%~30%.

Energy saving and consumption reduction, low-carbon economy. The use of endogenous denitrification of sludge does not require an external carbon source, and the remaining sludge is reduced by more than 30%, which reduces the cost of carbon source addition and sludge disposal, and reduces carbon input and carbon emissions at the same time. There is no need for internal reflux, which saves the high proportion of reflux set by the conventional process to improve the denitrification efficiency, and saves energy and reduces consumption.

Capped design, the ultimate land. Based on the characteristics of the project, the first and second phases of the common disinfection canal will be built, and the first phase of the disinfection canal will be renovated, so as to save land and investment costs.

The governance is well-organized, and the quality is obvious. The service area of Zhongshan Zhenjiashan Sewage Treatment Plant is close to 35 square kilometers, which is an important guarantee for the environmental pollution control of Zhongshan Water. It has greatly alleviated the problem of insufficient sewage treatment capacity in the region, significantly improved the environment of Zhongshan urban area, and improved the water quality of Shiqi River, which is of great significance for the sustainable use of water resources.

In recent years, BEWG has been continuously exploring new technologies and new products, actively practicing intelligent operation and intelligent management, and in-depth research on the new direction of future development of water affairs, and has accumulated certain experience and achievements. By the end of 2023, 28 technical products in four categories have been released, 17 provincial, ministerial and industry science and technology awards have been accumulated, 17 advanced and green technology lists, 28 typical cases and innovative achievements, and 356 valid patents.

In the future, BEWG will uphold the business tenet of "customer as the source, innovation as the road", continue to deepen the field of environmental protection and ecological governance, strengthen scientific and technological innovation, develop product technical strength and comprehensive service capabilities, and work hand in hand with colleagues in the industry to make greater contributions to green China!