How much carbon does an office chair have in it? Let's look at the product carbon footprint

Every day, there are many little-known stories happening around us, but they are closely related to life. For example, how much carbon emissions are there in the production of an ergonomic office chair? Let's go into the production workshop and look at the carbon footprint of the office chair.

"There are four branches in the production of this chair, which are cutting and sewing, die-casting, grinding and spraying of five-star feet, punching, welding and spraying of armrest back frames, and drilling and riveting nuts in wooden boards. In Anji, Zhejiang, the person in charge of a furniture company introduced in the production workshop.

Using a life cycle assessment method based on relevant international and national standards, the Service Manufacturing Research Institute in Hangzhou, Zhejiang Province evaluated and calculated the carbon footprint of the chair. "We pay attention to the carbon emissions of the whole process from 'raw material acquisition' to 'product manufacturing', and calculate the carbon emissions of the raw materials, each production link and the final assembly and packaging link of the chair, so as to form a complete carbon footprint report. A researcher at the Service-oriented Manufacturing Research Institute said.

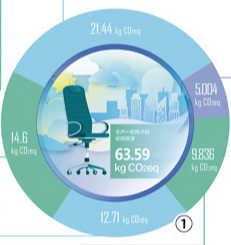

According to the product carbon footprint report of the Service Manufacturing Research Institute, the carbon emissions and total carbon emissions of the four production links and final assembly and packaging links of this chair are schematic.

In the five-star foot spraying shop, large furnaces are connected to a production line that is several hundred meters long. The chair uses a centralized aluminum melting process, which reduces energy consumption by about 20% compared with the past, and the aluminum material is also made of 100% recyclable materials. According to the estimation of scientific researchers, the carbon emission of the whole production process of Wuxingjiao is 21.44kgCO2eq.

In the handrail and back frame production workshop, the manipulator is skillfully carrying out production operations such as punching and welding. It has been calculated that the carbon emission of this link is 14.6kgCO2eq.

At the end of the line, the cutting and sewing process is planned together with the final assembly and packaging process, "which reduces product turnover and reduces energy consumption during production and transportation." The person in charge explained that recyclable cardboard boxes and plastic films are used in the packaging process, and the original split product packaging method is changed to integrated carton packaging, which can achieve 100% recycling of packaging materials.

"The production process of this chair is relatively complex, and through the selection of more recyclable raw materials and the transformation of energy-saving technology in the production process, energy saving and carbon reduction have been achieved. The final carbon emission of this chair is 63.59kgCO2eq. The researcher said.

From the carbon footprint of an office chair to the increasing use of solar energy to light up people's lives, the story of green and low-carbon development in the new era is constantly unfolding around us.