Daikin Fluorine Chemical: Leading the high-quality development of the fluorine chemical industry with the concept of green environmental protection

Daikin Fluorine Chemical (China) Co., Ltd. is a fluorine chemical manufacturer established by Daikin Industries Co., Ltd. in Changshu on April 8, 2001. Japan's Daikin Industry Co., Ltd. is a large-scale group company integrating air conditioning, fluorine chemistry, hydraulic machinery, special machinery and other businesses, with a history of 99 years since its establishment in 1924, with 347 group subsidiaries around the world and more than 90,000 employees worldwide, and has been in a leading position in the field of global air conditioning and fluorine chemistry.

office block

The company is located in Changshu New Material Industrial Park, covering an area of 490,000 square meters, mainly engaged in the production, processing, sales and after-sales service of fluorine chemical products. It has branches in Beijing, Shanghai, Guangzhou and Shenzhen, with more than 1,100 employees. The company's leading products are PTFE, fluoroelastomer, fluorine coatings, molten fluorine resin, hexafluoropropylene, new refrigerants, coating antifouling agents, etc. Since its establishment, the company has always adhered to the environmental protection concept advocated by Daikin Group's business philosophy and corporate ethics, attaches great importance to safety and environmental protection, and has invested a total of 200 million yuan in environmental protection facilities.

R&D center

Leading the environmental society and complying with environmental laws and regulations

Daikin Fluorine Chemical (China) Co., Ltd. adheres to the Daikin Group's business philosophy of "leading the environment and society", and regards the protection of the global environment as our unshirkable mission. Therefore, we will actively take various measures to reduce the environmental impact of our production and business activities.

At the beginning of the establishment of the company, it installed more advanced safety and environmental protection facilities than Daikin's factories in Japan and the United States, and continuously upgraded with the addition of construction projects to ensure that the discharge of waste water and exhaust gas is far lower than the standard requirements of national regulations.

At present, the company has built a wastewater treatment system, a special incinerator for organic waste liquid, a waste gas washing and absorption device, a dust filtration device, etc., and a supporting construction of safety and environmental protection monitoring facilities such as an online monitoring system for drainage water quality, an online monitoring system for the atmosphere at the plant boundary, an online monitoring system for incinerator flue gas, and a monitoring and alarm system for harmful gas leakage in the device. These equipment are networked with the company's DCS online control system, Changshu Environmental Protection Bureau, Changshu Safety Supervision Bureau, and Park Emergency Center, which ensure the safe and stable operation of the company's devices and will not have a negative impact on the external environment.

While complying with environmental laws and regulations, the company also puts forward strict environmental protection requirements for suppliers, we will inform the group's latest green procurement policy, and implement continuous environmental monitoring to relevant parties to ensure that the other party does not have environmental violations and regulations, and urge the other party to establish and operate a sound environmental management system and implement advanced environmental protection measures;

Central control room

Energy conservation and emission reduction are consistent concepts and actions

Fluorocarbon gas emission reduction: The company has independently put forward the requirements for reducing carbon dioxide emissions at the beginning of the establishment of the plant, and sets a reduction target every year for control. For the unorganized exhaust of the company's new refrigerant production device during annual inspection, sampling, filling, and product switching, the refrigerant recovery system is increased, and the unorganized exhaust of the mobile TANK tank for annual inspection is recovered, and the fluorocarbon gas emitted by the tetrafluoroethylene production unit, hexafluoropropylene production unit, and vinylidene fluoride production unit in the sampling and filling process is all recovered. These initiatives have significantly reduced the company's carbon dioxide emissions due to fluorocarbon gas.

Harmless emulsifier: In order to reduce the adverse impact of PFOA emulsifier on products and the environment, the company completed the switch 4 years ahead of the national requirements, and began to use new environmentally friendly emulsifiers to replace traditional PFOA emulsifiers in 2009. Due to the high cost of new emulsifiers, the company will increase the investment of more than 10 million yuan every year for the use of new environmentally friendly emulsifiers. At the same time, the treatment device of emulsifier wastewater has also been renovated, so that the treatment rate of emulsifier reaches 98%, which greatly reduces the discharge of emulsifier in wastewater and the generation of waste.

Wastewater recycling: For large water users, how to reduce water use and wastewater discharge is a very serious issue. To this end, the company has set up a wastewater and waste reduction team, composed of professionals from the manufacturing department, technology department, engineering department, safety and environment department, etc., to discuss various water use and drainage in the manufacturing department, and finally decided to build a water reuse device, which was put into use in 2014. After the reclaimed water recovery device was put into operation, the company's water consumption was reduced by 20% and wastewater discharge by 23%, and the recycling and reuse of steam condensate, vacuum pump circulating water, and RO membrane drainage were subsequently promoted, and the company's water consumption and wastewater discharge were reduced by 5.8% and 10% after the implementation. In the future, the members of the Wastewater and Waste Reduction Team will continue to discuss issues that can be promoted, and will continue to work towards the company's F25 and F30 goals of "zero wastewater discharge".

Reclaimed water reuse

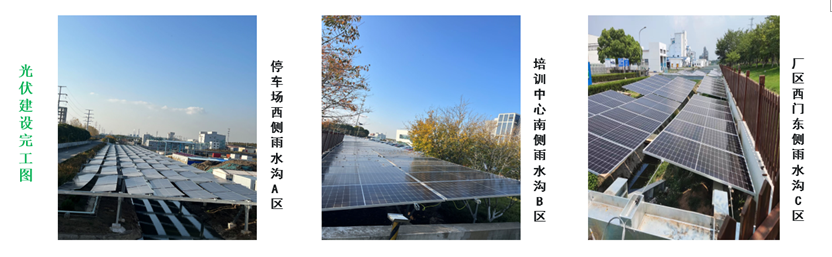

Photovoltaic power generation project: In 2016, the company introduced a 100kW phase I photovoltaic power generation project, the electricity generated by photovoltaic is first used within the plant, and when the plant cannot be fully consumed, the photovoltaic power is reversed to the power grid side through the plant distribution system for other loads in the plant. In September, the power generation system was put into use, and the daily power generation was displayed from the employee channel, so that each employee could know the power generation of the day, which improved the environmental awareness of employees, and in 2022, the company invested about 6 million yuan in the rainwater ditch on the west side of the company's parking lot, the rainwater ditch on the south side of the training center, and the rainwater ditch on the south side of the training center. The second phase of the photovoltaic power generation project on the east side of the company's west gate was put into use after the completion of grid connection acceptance in November 2022, with an estimated annual power generation of 1.168 million kWh, which greatly reduced the company's carbon dioxide emissions, reflecting the company's unshirkable mission of protecting the earth's environment, and actively taking various measures to reduce the environmental load.

Photovoltaic power generation

Environmental protection and public welfare to give back to the society

While the company continues to grow and develop, it is also actively undertaking its own social responsibility. We are actively contributing to the local community through activities such as cherry blossom festivals, community cleaning, blood donation by employees, donations to local welfare homes, nursing homes, and Haiyu mothers' organizations, as well as scholarship donations to Haiyu elementary and junior high schools.

Since 2014, the company has built a "Golden Cherry Garden" covering an area of nearly 20,000 square meters, and has held ten consecutive cherry blossom festivals. Every year, when the cherry blossoms are in full bloom, government officials, representatives of surrounding residents and enterprises, student representatives, and family members of employees will be invited to participate in the cherry blossom viewing, visiting the workshop & exhibition hall, participating in environmental protection activities and charity sales, which greatly deepens the understanding of community residents about Daikin, feels the warmth and harmony of Daikin culture and Daikin Family, and completely eliminates the impression of surrounding residents that the chemical plant is unsafe and environmentally unfriendly.

Daikin Cherry Blossom Festival

Since 2013, the company has held an annual "Flying Green Heart" environmental protection activity, inviting primary school students from nearby schools to participate, and will also go into the campus to interact with children in environmental protection. By watching environmental cartoons and interacting with questions, environmental paintings, environmental experiments, environmental sitcoms, and environmental speeches, the children gained Daikin's environmental protection concept and environmental protection knowledge while being entertained, and also influenced their families through the children.

Community cleaning has been carried out since 2013. While managing the company's internal environment, because the company is close to the Yangtze River in the north, in order to protect the tidal flats of the Yangtze River, we put forward the social responsibility activity of "protecting the mother river", and we will organize Daikin employees and their families to participate in the "protect the mother river" community cleaning activity every quarter, and pick up the non-degradable garbage by the river and place it at the community garbage station, which has been unanimously praised by the surrounding residents.

The company's labor union will also organize employees to visit the elderly in nursing homes every year, donate to children in welfare homes, donate to poor children in Guizhou, establish outstanding student grants for Haiyu Primary School and Haiyu Middle School, donate blood from foreign colleagues, and actively participate in tree planting activities and social responsibility activities in the park.

Center

In 2005, the company won the "Changshu Environment-friendly Enterprise", in 2006, the company won the "Suzhou Environment-friendly Advanced Enterprise", since 2011, the company has been rated as "Changshu Green Enterprise", in 2014, the company was recognized by the group as the first overseas "Super Green Heart Factory", and in 2018, the company was awarded the "Second Batch of Green Manufacturing Plants" by the Ministry of Industry and Information Technology of the People's Republic of China In 2021, the company was awarded the "2020 Provincial Water-saving Enterprise" by the Jiangsu Provincial Department of Water Resources and the Jiangsu Provincial National Development and Reform Commission, and in 2022, the company was awarded the "A-level Environmental Performance Enterprise" by the Jiangsu Provincial Department of Ecology and Environment.

"Ahead of society in terms of environmental protection" is the business philosophy of Daikin Group, and it is also deeply engraved in the hearts of every Daikin person. We will continue to attach great importance to environmental protection while steadily increasing efficiency, and make positive contributions to economic and ecological construction.