The steel industry has shown resilience in the face of challenges

Relying on the two major enterprises of Shandong Iron and Steel Group and Rizhao Iron and Steel Group, Shandong Rizhao Donggang District will focus on the development of supporting service industries around the iron and steel industry to promote the high-quality development of the county economy. Photo by Xinhua News Agency reporter Guo Xulei

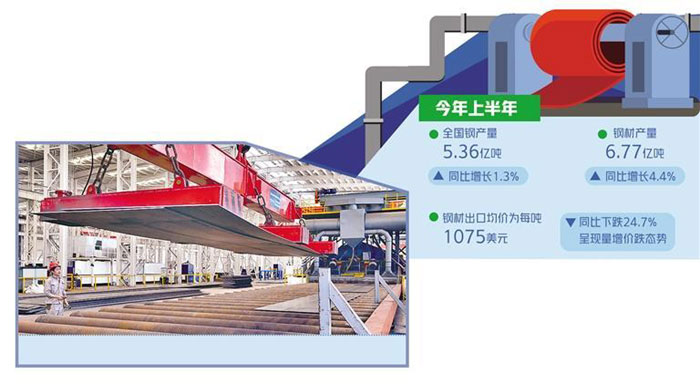

In the first half of this year, the national steel output was 536 million tons, a year-on-year increase of 1.3%; steel output was 677 million tons, a year-on-year increase of 4.4%; Steel exports were 43.58 million tons, a year-on-year increase of 31.3%. At the same time, the efficiency of iron and steel enterprises has decreased significantly year-on-year, and the financial risk is controllable.

Tan Chengxu, president of China Iron and Steel Association, said that in the face of many "pains" of transformation and upgrading and a more severe market environment, the iron and steel industry adheres to the general tone of seeking progress while maintaining stability, strives to achieve overall stability in production and operation, continuously improves core competitiveness and enhances core functions, and promotes new breakthroughs in high-end, green and intelligent development.

Exports have grown substantially

Since the beginning of this year, China's steel export momentum has been relatively strong. In the first half of the year, 43.58 million tons of steel were exported, a year-on-year increase of 31.3%, and 1.67 million tons of billets were exported, a year-on-year increase of 112.6%; imported steel was 3.74 million tons, down 35.2% year-on-year, and imported billets were 1.18 million tons, down 68.5% year-on-year; The net export of crude steel was 42.11 million tons, a year-on-year increase of 64.3%.

"The competitiveness of China's iron and steel industry in the international market has been further enhanced, and the export of high value-added products has increased significantly, and the proportion of plate exports has reached 66%, a record high." Jiang Wei, deputy secretary of the Party Committee, vice president and secretary general of the China Iron and Steel Association, said.

Masteel is a national manufacturing single champion demonstration enterprise, with a global market share of more than 10% of wheel axle products. In the first half of the year, Masteel's revenue achieved 110.5% of the annual target, a year-on-year increase of 14.4%; export sales revenue increased by 34.9% year-on-year; New contracts increased by 22.6% year-on-year.

Tiangong International is a national key high-tech enterprise, and its high-speed tool steel products have been rated as national single champion products. The company continues to enhance the advantages of high-end products and high added value, and the proportion of exports accounts for nearly half of the company's marketing. "In June this year, the export value of Tiangong International products exceeded 40 million US dollars, once again refreshing the export performance of a single month." Wu Suojun, general manager of Tiangong International, said that recently, the 7,000-ton fast forging project was officially put into operation, which has become an important symbol of Tiangong International's entry into the field of integrated large-scale die-casting. The company will further enrich and meet the market demand for high-end products, and continue to enhance its competitiveness.

值得注意的是,钢材出口总体呈现量增价跌态势。上半年,钢材出口均价为每吨1075美元,同比下跌24.7%。中钢协有关负责人提醒说,上半年钢材Exports have grown substantially,缓解了国内市场供需压力,但在全球经济增速放缓及贸易保护主义抬头的背景下,可能引起贸易摩擦案件的反弹,需引起行业重视。考虑到前期接单情况及人民币贬值影响,预计下半年钢材出口量增幅将收窄。

Guaranteed smooth operation

China is the world's largest producer and consumer of steel, and steel production is mainly to meet domestic demand. In the first half of the year, as the supply of steel was stronger than the demand, the decline in steel prices was greater than the decline in costs, and the overall efficiency of the steel industry declined significantly.

According to the data of China Iron and Steel Association, in the first half of the year, the operating income of key member iron and steel enterprises was 3.19 trillion yuan, a year-on-year decrease of 5.56%, the operating cost decreased by 3.06% year-on-year, and the decline in income was greater than the cost decline by 2.5 percentage points, and the total profit was 33 billion yuan, a year-on-year decrease of 68.8%; The average sales profit margin was 1.03%, down 2.1 percentage points year-on-year, and the loss area reached 44.6%, up 17.4 percentage points year-on-year.

In the face of the current situation of supply and demand imbalance in the market, the backbone iron and steel enterprises insist on determining production by sales, production by efficiency, and sales by present. At the same time, we will further promote management reform and actively carry out benchmarking and tapping potential. Shagang, Shandong Iron and Steel, Pangang Xichang and other steel enterprises have done a good job in reducing costs and increasing efficiency, seized the key to break through bottlenecks, and continued to promote the improvement of indicators and the reduction of costs.

"We are working with relevant departments to speed up the formulation of a work plan for the steady growth of the steel industry, from both ends of supply and demand, focusing on stable operation, expanding demand, promoting reform, helping enterprises, and strengthening momentum." Zhang Haideng, deputy director of the Department of Raw Materials Industry of the Ministry of Industry and Information Technology, said at the sixth meeting of the sixth council (enlargement) of the sixth session of the China Iron and Steel Association held recently.

To ensure the smooth operation of the steel industry, multiple measures are needed. Tan Chengxu said that on the basis of the research on production capacity, we should study and create a new capacity governance mechanism that adapts to the new development environment, has both energy consumption and carbon emission policy constraints, industry self-discipline and government supervision, and conforms to the laws of the market, and accelerates the implementation. Actively integrate into the construction of a unified national market, support leading enterprises as the main body of implementation, and implement comprehensive policies to promote restructuring and improve industrial concentration. In addition, it is necessary to strengthen industry self-discipline.

China's iron ore resources are highly dependent on imports, and the sources of imports are concentrated, and the price of iron ore continues to fluctuate at a high level, resulting in the serious erosion of the profits of China's iron and steel industry. For the development and construction of key domestic iron ore projects, Huo Fupeng, deputy director of the Industry Department of the National Development and Reform Commission, proposed that while ensuring the normal production of existing mines, it is necessary to accelerate the construction of new projects. In particular, 10 million tons of iron ore concentrate projects such as Dataigou Iron Mine and Honggnan Mine should be implemented in key tasks such as the approval of mining rights, the transfer of mining rights, and the indicators of land use and energy consumption.

Accelerate low-carbon development

As China's economy shifts from a high-speed growth stage to a high-quality development stage, steel demand has entered a peak plateau area, and it is the general trend for the steel industry to reduce quantity and improve quality.

From the perspective of consumption structure alone, steel used in the construction industry decreased from 58% in 2020 to 53% in 2022, and steel used in manufacturing increased from 42% to 47%. The continuous growth of automobiles, home appliances, ships, wind power steel, photovoltaic steel, etc., effectively supported the growth of the variety and quantity of steel used in the manufacturing industry.

As the steel market jumps to a higher level of dynamic balance between supply and demand, the trend of enterprises is becoming increasingly differentiated, and the transformation and structural adjustment are accelerating. Since the beginning of this year, Shougang Zhixin Electromagnetic has completed and put into operation the world's first 100% thin-gauge high-magnetic induction oriented electrical steel production line, and two oriented electrical steel products have achieved the world's premiere. Relying on excellent market competitiveness, in the first half of the year, the output and sales volume of Shougang electrical steel completed 54.4% and 52.2% of the annual budget respectively, and the output of non-oriented high grades, new energy products and oriented electrical steel products increased by 14%, 59% and 39% year-on-year respectively.

In the first half of the year, Anshan Iron and Steel Co., Ltd.'s 33 mm thick X80 grade large strain pipeline steel plate achieved the world's first launch, Xingang successfully rolled the world's thinnest and tallest grade non-oriented electrical steel, and Shagang's super-large welding heat input high-end ship plate steel products filled the domestic gap... Technological innovation has borne fruit, and China's steel hard core strength has continued to increase.

Green and low-carbon development is an inherent requirement for the high-quality development of the steel industry. In the face of downward pressure, the ultra-low emission transformation of the steel industry has been steadily promoted, and the level of environmental protection has continued to improve. As of the end of June, a total of 87 iron and steel enterprises have completed ultra-low emission transformation and evaluation and monitoring, of which 62 enterprises have completed the whole process ultra-low emission transformation, involving about 314 million tons of crude steel production capacity, and 25 enterprises have completed the ultra-low emission transformation of some processes, involving about 114 million tons of crude steel production capacity. The comparable energy consumption and pollutant emissions per ton of steel in the steel industry continue to decline.

On May 17 this year, the EU's Carbon Border Adjustment Mechanism (CBAM, or carbon tariff) officially came into effect, marking the implementation stage of the international carbon pricing mechanism. "This has a limited short-term impact on the export of China's steel industry, and the long-term impact is rising." Fan Tiejun, president of the Metallurgical Industry Planning and Research Institute, analyzed that with the continuous advancement of the EU's deep emission reduction policy, the gradual withdrawal of the EU's free quotas, the gradual expansion of CBAM coverage, and the expansion of carbon price spreads, China's steel products will need to bear higher export costs to Europe, and other developed countries may also set up trade barriers similar to CBAM, which will have a more extensive impact on China's steel industry. In addition, downstream industries such as automobiles have begun to pay attention to the carbon emissions of steel products, and automotive steel manufacturers with long processes are facing huge challenges.

Recently, China's first volume of ultra-low emission low-carbon material automotive steel produced by using high-quality and high-proportion hydrogen metallurgical clean raw material DRI products has provided a data package to the German BMW Group to officially open the material certification after the HBIS Group Tangsteel Company rolled off the production line and passed the inspection. According to the memorandum of cooperation signed by the two parties, starting from mid-2023, HBIS's low-carbon automotive steel will be gradually used in production models at BMW's Shenyang production site.

It is understood that HBIS has built the world's first 1.2 million tons of hydrogen metallurgy demonstration project, reducing carbon emissions from the source and opening up a new path for the production of low-carbon materials required by the automotive industry.

"From the perspective of development trends, when downstream customers choose steel products, they not only pay attention to product quality, but also pay attention to the green and low-carbon production process." The relevant person in charge of HBIS said that the EU carbon tariff has brought opportunities for the development of HBIS's green and low-carbon products in the European market, and the global market is broad.