Yuxin shares: focus on LPG carbon four deep processing, to be specialized, refined, and stronger

In Huizhou Daya Bay Petrochemical Park, there is a company that has long attached importance to the concept of ESG development and responded to the "double carbon" It is Hunan Yuxin New Energy Technology Co., Ltd. (hereinafter referred to as Yuxin Co., Ltd.). Although the maleic anhydride market is sluggish, most of the operating rates are not high, but Yuxin's stock equipment is in full production. On November 13, the degradable materials research team of China Chemical Industry News walked into this company that focuses on the field of LPG carbon four deep processing and continues to be specialized, refined and stronger.

Many technologies are the first in China

Founded in October 2009, Yuxin shares, has a history of 14 years, has been committed to the process research and development and production of chemical products with LPG carbon four as raw materials, through advanced technology and its own patented technology to produce products including basic chemical products, clean energy and new materials, the company's main production base is located in Huizhou Daya Bay Petrochemical Zone, one of the seven major petrochemical industry bases in China, and relying on CNOOC Huizhou Petrochemical, CSPC Shell and other large petrochemical enterprises. The company has successfully created many sets of LPG deep processing product production equipment, the main products include methyl tert-butyl ether, isooctane, maleic anhydride, isopropanol, etc. Although it is an old chemical product, Yuxin uses new technology to minimize the cost of products. At present, it has developed into the largest LPG C4 deep processing enterprise in South China.

Hu Xiannian, chairman of Yuxin Co., Ltd., told the research team that the company adheres to the concept of continuous innovation, has the ability to innovate in an all-round way of the device, and carries out innovative technological transformation in the process package: the company combines the actual situation to conduct a comprehensive analysis and in-depth combing of the device construction and design in the early stage, and carries out all-round independent innovation on the process package according to local conditions. In the demonstration of new project technology: the company has gone through a long period of technical comparison and screening for each new project, and selected the most advanced technology package in the industry for device production.

The company has created a new process of SBAC, which adopts the direct synthesis method of liquefied gas and acetic acid, which reduces the production cost and makes SBAC very competitive in the market, and the current purity can reach more than 99.5%, realizing the industrialization of direct synthesis of SBAC from butene and acetic acid for the first time. The 100,000 tons/year butanone co-production 130,000 tons/year ethyl acetate project is the first to adopt the transesterification process, and the original process has obvious advantages: the company uses SBAC as an intermediate product transesterification method not only has a high conversion rate of raw materials, but also has more mild reaction conditions and low energy consumption costs. It has the world's largest single maleic anhydride plant (150,000 tons/year), and all indicators are at the leading level in the industry.

Unique and innovative thinking

"Only through innovation can we adapt to change, which is the most effective means. The company has been focusing on products and raw materials related to R&D research to the end, and some new product applications are made through some experiments, for which we have specially built a R&D building. Secondly, based on the market's technological innovation, find the market, because people's needs are always changing, you have to find the right demand after the change and then research and development, that is, to use the forced thinking to do research and development, the company has a doctor from Peking University in front of me in the research market, analysis of those products may use our raw materials production, we must figure it out, at the same time to have a certain professionalism, and even some need to do some exploratory experiments, but also understand engineering, to avoid behind closed doors, research and development out of the market. In fact, the core competitiveness of our technology lies in original innovation, combination innovation, introduction of technology, digestion and absorption, and re-innovation, and strive to achieve the lowest cost. To do the complete industrial chain, every link must be innovated, so that the industry can not be copied," said Hu Xiannian of Yuxin shares.

According to the research team, Yuxin has been committed to the process research and development and production of chemical products with LPG carbon four as raw materials, independent innovation and research and development of refined sec-butyl acetate products and preparation methods of sec-butyl acetate, and won the "Invention and Entrepreneurship Award" at the 10th International Invention Exhibition and the 3rd Invention and Innovation Forum. In terms of process technology such as n-butene to isobutylene, isobutane to isooctane, n-butane to maleic anhydride, etc., it has entered the international and domestic advanced ranks.

At the same time, the company has mastered core catalyst technologies such as maleic anhydride, which can realize the perfect combination of process and catalyst. Gradually promote the optimization of catalysts and reactors, fundamentally improve the conversion rate and selectivity of reactions, and the activity and stability of catalysts are better than similar foreign products.

The key to technological innovation lies in talent. Yuxin has always attached importance to technology research and development and independent innovation, especially market-based innovation and innovation in each link of the complete industrial chain, and has taken the introduction and training of talents as the top priority of its work.

At present, Yuxin has 174 R&D + engineering technicians, including 4 doctoral students and 69 master's students, and the relevant technical R&D personnel have rich scientific research experience and practical experience. The company has been awarded the National High-tech Enterprise, the National Advanced Collective of Petroleum and Chemical Industry, the Top 500 of the National Petroleum and Chemical Industry, China's Quality and Integrity Enterprise, and the Innovative Enterprise of Guangdong Province. It has Guangdong Provincial Engineering Technology R&D Center, Guangdong Enterprise Technology Center, a Huizhou Swan Plan innovation team, and two Huizhou Swan Plan leaders. It has also drafted the industry standards "Refined sec-butyl acetate" and "alkylated isooctane" group standards. In the past three years, the company has invested more than 350 million yuan in R&D and 49 patents (25 invention patents, 24 utility model patents), 10 new patents every year after listing.

With the gradual advancement of the domestic "plastic ban", degradable plastic-related industries will usher in vigorous development. At present, the company has built a 60,000 tons/year PBAT degradable plastic device, based on technological innovation genes, the first production of low-cost degradable plastics, and the product quality has reached the standard of excellent products. Produce degradable plastic products with better quality than existing products and prices close to ordinary plastics.

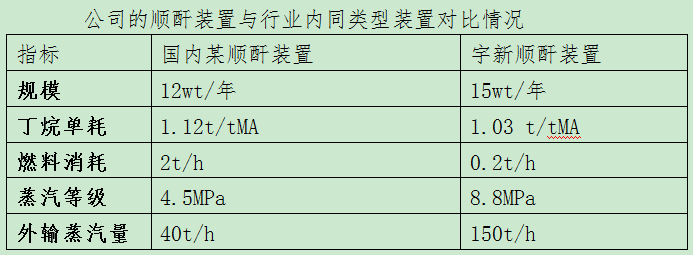

In terms of maleic anhydride industry and supporting facilities, according to Hu Xiannian, chairman of Yuxin Co., Ltd., the company has built the world's largest single set of maleic anhydride production capacity of 150,000 tons/year and 120,000 tons/year BDO Production is expected to start in the first quarter of 2024. And according to the market situation, the flexible switch to the production of BDO and GBL. In terms of supporting, on October 31, the company's annual output of 500 tons of maleic anhydride catalyst project was successfully put into operation, and the products produced reached the excellent level of similar products at home and abroad. It has created conditions for the company to improve the maleic anhydride process and completely change the situation of excessive investment, high production cost and serious pollution of maleic anhydride device, which not only reduces the production cost of maleic anhydride, but also makes a major breakthrough in the independent technology of catalyst. The sale of some products will also become a new profit growth point for the company. At the same time, the company has always adhered to the concept of energy saving, and the energy consumption level of maleic anhydride device has maintained a leading position in the industry, and at the same time, the by-product steam has been recycled, and the economy is good. The steam generated by the company's maleic anhydride unit can be recycled and used in the downstream butanone plant and external sales, saving energy and improving the economic benefits of the company's equipment. In the third quarter of 2023, the company's revenue will be 4.666 billion yuan, and the net profit will be about 382 million yuan, a year-on-year increase of 31.43%.

Development planning and strategy

Chairman Hu Xiannian told the research team that in the future, the company will make every effort to build a specialized, refined, special, new, flexible and low-carbon industrial development system. Adhere to the comprehensive utilization of all components of carbon four, adhere to the green circular economy, adhere to the overall optimization of technology, equipment and catalysts, and continue to build the core competitiveness of technological innovation with Huizhou New Material Industrial Park as the base, LPG as the main raw material, and maleic anhydride by-product steam as the driving force. In the future, the company will continue to expand new production capacity, deepen the layout of the industrial chain of C4 new materials, and do the downstream of fine maleic anhydride and isobutylene, so as to increase added value. In 2023, the company has built a 100,000 tons/year butanone co-production project of 130,000 tons/year ethyl acetate, 60,000 tons/year PBAT, 500 tons/year maleic anhydride catalyst, etc. From 2024 to 2025, the company will build a new 1,500 tons/year copper-based catalyst, 60,000 tons/year PBS, 46,000 tons/year PTMEG, 190,000 tons/year DMS, Brocade 130,000 tons/year BDO, 240,000 tons/year maleic anhydride and other projects, and strive to achieve 20000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

In the view of the research team, market-based innovation, adherence to original innovation, combination innovation, and re-innovation of introduced technology are the main reasons why the process technology, operation level and energy consumption level of Yuxin's main production equipment have been in the leading position in the industry for a long time. With the market-oriented, benefit-first flexible production model, every link of the complete industrial chain must be innovated, and strive to achieve the lowest cost is the magic weapon for Yuxin to win in the market.