Analysis on the sustainable development prospect of water industry under the background of "dual carbon".

Water industryAs an energy-intensive industry, the consumption of electricity and chemicals directly or indirectly contributes to a large amount of greenhouse gas emissions. Therefore, it is necessary to implement low-carbon transformation and reduce the industry as soon as possible through technological innovation, efficient and clean use of energy, intelligent production and other meansCarbon emissions,有助于为全行业提供更为广阔的发展空间。同时,以清洁能源替代化石能源消耗,建立绿色电力使用渠道,将有助于进一步抵消行业Carbon emissions,赋能产业Green and low-carbon transformation。

1 Water industry与Carbon emissions紧密相关

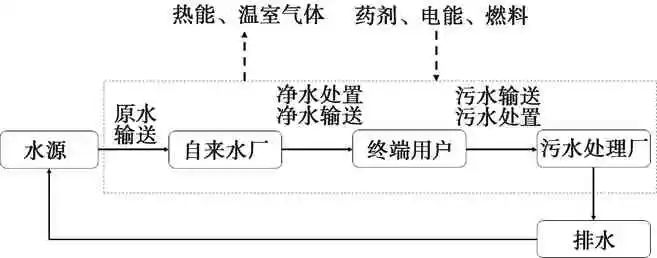

Water industry是指由原水、供水、节水、排水、污水处理及水资源回收利用等构成的产业链,如图1所示。城市Water industry是城市发展、居民生活和工业生产等的基础,其行业上游是原水的获取,水资源获取的形式(地表水、地下水)及水源地的品质情况直接影响着供水成本与能耗;行业下游是污水与污泥的处理处置,城镇居民耗水量、节水情况及污水厂工艺技术和智能化管理水平将直接影响污水处理的综合能耗及药剂消耗。

图1 一种典型的城市Water industry系统

据数据统计,2020年全国城镇污水处理全过程Carbon emissions量为3 416.0万t CO2,碳抵消量为769.1万t CO2,净排放量为2 646.9万t CO2,全国城镇供水系统Carbon emissions量超过2 200万t CO2。由此可见,Water industry实现碳减排对我国早日实现“碳达峰”“碳中和”有着重要意义。

1.1 供水的Carbon emissions

The raw water obtained from the water source is transported to thousands of households through the raw water pipe network, treated by water plants, and transported by the water supply pipe network. In the process of raw water pipeline network transportation and water supply pipeline network transportation, it needs to be treated by multi-stage pumping stations and pump rooms, and the indirect emission of electric energy consumed by water pumps in this process is the main form of greenhouse gas emissions. In general, greenhouse gases are not directly emitted in the treatment process of water plants, and their indirect emissions are derived from the energy consumption generated by the operation of the equipment, as well as the chemical consumption caused by the addition of chlorine, flocculants and disinfectants in the pretreatment process.

赵荣钦等结合郑州市水源供给情况及相关数据进行分析计算,结果表明,城市依靠地下水开采和南水北调供水的取水系统Carbon emissions值达0.14 kg/m3,制水和输配水过程能源强度分别为0.543 kW·h/m3和0.320 kW·h/m3。依照2020年全国单位火电发电量CO2排放量换算,制水和输配水过程的CO2排放量分别为0.452 kg/m3和0.266 kg/m3,制水过程对Carbon emissions的贡献率更大。

1.2 污水处理的Carbon emissions

生活污水处理的Carbon emissions形式主要分为直接排放和间接排放。其中,直接排放一般为污水处理过程中,由于水中有机污染物被降解,释放了CO2、CH4和N2O等温室气体,进入大气;间接排放一般为污水处理过程中,所使用的包括电、气和药剂等所折算的Carbon emissions。

Ma Boya et al. proposed through research that compared with direct emissions, the current research on indirect emissions is more in-depth, and the technical direction is also clearer, and the relevant research mainly focuses on energy saving and consumption reduction and sewage energy reuse. The results show that in the process of sewage treatment, indirect emissions caused by electricity consumption and direct emissions of nitrogen oxides generated in the process of denitrification are the main components of greenhouse gas emissions, accounting for 80%~90% of the total emissions.

2 Water industry碳减排可行性与路径分析

2.1 Feasible pathways for carbon reduction in water supply processes

供水过程中的Carbon emissions主要集中在管网输送及处理设备用电、药剂使用,减少药剂消耗、推动节能减排、减少单位能耗Carbon emissions量等措施均有助于实现供水环节的碳减排。

2.1.1 Water source protection

现代饮用水在加工处理过程中,需经加氯消毒去除大部分微生物,先后经混凝沉降、煤砂滤池、活性炭池的过滤和吸附进行处理。因此,优质的水源地将提供更高品质的原水,相应地,其处理过程所消耗的药剂量更低,Carbon emissions更低。强化对水源地的保护,不仅有助于提高生态环境质量,还能够降低净水处理过程中间接Carbon emissions。

2.1.2 New energy applications

提高非化石能源发电量是电力行业实现“碳达峰”的重要途径。研究表明,水厂的能源消耗占到总成本的20%以上,其中包括水泵、风机等在内的关键能耗设备耗能超过总能耗的85%。中电联相关数据表明,2020年和2021年全国全口径非化石能源发电量分别为9.8×108kW和1.11×109kW,分别占到当年总发电装机容量的44.7%与47%。提高水厂用电中非化石能源的比例,可有效降低净水处理过程中的能耗与Carbon emissions。东京自来水公司结合试运行计算与实际发电成效,评估太阳能发电设备和水力发电设备的使用寿命分别为20年和22年,在公共系统的支持下,通过自用和售电获利的方式,可适当降低电力成本、减少Carbon emissions,有望在寿命期内收回建设和维护成本。丰顺大罗水厂的建设过程中充分利用了厂区建筑物房顶及池体,通过采用“门式刚架屋面加盖”等方式的光伏设备铺设,为厂区生产用电提供保障并抑制了池体内水藻生长。

2.1.3 Technological innovation

In order to achieve efficient, less manual and automated equipment operation, the application of electrical automation and artificial intelligence to water plants will help improve production management efficiency, ensure water supply reliability, reduce errors and reduce energy consumption (Figure 2). Taking Suzhou Wuzhong Water Plant as an example, the plant realizes accurate sludge discharge through the application of electrical automation control system, and the automatic dosing system can achieve multi-parameter linkage with water quality, process water quality and factory water quality, and effectively reduces energy consumption and improves work efficiency through data guidance production management. Its self-developed integrated chlorine replenishment device for the pipeline network can realize fully automated operation of the network, reduce the residual chlorine index at the front end, effectively improve the residual chlorine of the downstream pipe network, and improve the quality of water (Figure 3). In the automation transformation, Wuhan Yushidun Water Plant has built an automatic dosing control system and an automatic inlet and drainage control system controlled by PLC to achieve uniform water distribution, stable water output and reduce energy consumption.

Fig.2 The automatic intelligent dosing system reduces the turbidity fluctuation of the effluent of the sedimentation tank by 50% and the fluctuation of the residual chlorine index of the effluent by 45%

Fig.3 The integrated chlorine replenishment device of the automatic pipe network realizes water purification disinfection and automatic detection

In work practice, electrical automation control technology has an obvious positive effect on improving production efficiency, reducing labor costs, and reducing energy and material consumption, but in the face of some production early warnings, compared with skilled technicians and engineers with rich work experience, there is a lag in processing, and the ability to solve sudden problems is limited, and manpower is still needed. Therefore, it is particularly important to promote the development of artificial intelligence technology in the water supply industry, which can rely on artificial neural networks and self-learning capabilities to predict water demand and intelligently regulate the power of equipment, ensure the stability of water output in real time according to the water quality adjustment process, intelligently predict water quality fluctuations and give timely warnings.

2.1.4 Water conservation measures

China's water supply pipe network construction span is large, the types of pipelines are generally steel pipes, cast iron, ductile iron, prestressed concrete, plastics, etc., the pipeline layout is increasingly complex and tight, affected by geological changes, pavement settlement, construction, material aging, road vibration and other factors, water pipeline leakage is difficult to avoid. The water leakage caused by leakage will further increase the amount of water treated by the water plant in the face of the same water demand, and it is necessary to strengthen the learning of professional staff in pipe network inspection and leak detection, and update the detection technology to ensure the stable operation of the water supply network.

2.2 Feasible pathways for carbon reduction in the drainage process

与钢铁、有色金属行业等高耗能的行业相比,污水处理系统的能耗因其相对较低,被人们长期忽视,但实际上污水处理也属于能耗密集型行业。通过强化资源再利用、优化污水处理工艺与技术、降低单位用电Carbon emissions等有助于污水厂实现节能减排。

2.2.1 Wastewater reuse

For the treated tail water that meets the non-potable water standard, it can be tested to ensure that it meets the relevant reuse water quality requirements, and can be used for water that does not come into direct contact with the human body, such as water that can be used for greening in the factory/park, fan cooling circulating water and filter belt flushing water for belt dehydrators.

2.2.2 Technological innovation

生活污水的处理技术多种多样,但目前应用广泛、技术成熟的处理技术一般是通过外部添加能源、碳源或药剂对污染物进行降解,此过程会向外界环境排放大量温室气体,减少额外能量、碳源的输入,将有助于降低污水厂Carbon emissions。在副产品利用方面,当前的工艺技术中多采用焚烧发电、厌氧消化产出甲烷、生物产氢等途径,对污水处理过程中其副产物污泥进行能源转化。例如,日本部分污水厂将热能用于供暖及融雪工程;德国卡地茨污水处理厂综合利用太阳能发电、废水发电、热能发电、沼气发电4种发电方式解决厂区自身电能需求;青岛光威污水处理厂、六圩污水处理厂利用沼气发电技术减少外部输入电能。Schaubroeck等与Besson等将生命周期评估法应用于奥地利Strass污水处理厂的工艺研究,表明污泥消化产生的沼气等可生产充足电力并对外输出并网,获取一定经济利益。图4展示了美国格雷沙姆污水处理厂通过工艺优化提高沼气产量,使用燃气发电机组将可再生沼气热电联产与太阳能发电协同利用,实现能源净零,厌氧发酵池的副产品仍可作为肥料回用于农田。

Wang Jingfan et al.'s research also pointed out that the sustainable process in the future is the new AB process, that is, section A is responsible for efficient carbon capture, the purpose is to capture the organic matter in the wastewater before biological oxidation, and then use it for energy recovery, and the implementation of new low-carbon technologies in section B (such as the use of anaerobic ammonia oxidation technology to reduce the external carbon source) to further remove pollutants from the wastewater.

2.2.3 New energy applications

国内污水厂的耗电量普遍达0.29 kW·h/m3,相较于美国的污水厂耗电量(0.2 kW·h/m3)而言,该数据显然远超发达国家。通过工艺改进,在降低单位废水处理耗电量的同时,减少的单位电耗Carbon emissions量将有助于降低厂区整体Carbon emissions量。污水厂占地较大、楼层较低,采用太阳能、风能等新能源将有助于减少厂区所用市电需求量(图5),Goswami等研究了在污水处理系统中开发浮动太阳能光伏(FSPV)系统,将光伏组件漂浮在水面上实现太阳能发电,15 MW太阳能光伏系统可向电网供能26 465.7 MW·h/年,减少蒸发788万m3的水,减少CO2排放量近52万t,有助于污水厂向可持续发展转型。刘玉涛等对山东某地下污水厂开展实例分析,论证了通过建设包含光伏发电、沼气发电等在内的多能互补综合能源系统,可实现污水厂的稳定供电,每年可节约标准煤2 855 t,减排CO2以及其他大气污染物排放7 699 t。

3 Summary and Recommendations

3.1 Building "low-carbon water" is the only way to move towards "carbon neutrality" in water affairs

水是人类日常生活和社会发展不可或缺的重要物质资源,污水直排所产生的黑臭水体在厌氧环境中会增加大量Carbon emissions。Water industry的减碳举措既能够直接推进水环境治理环节的Carbon emissions协同控制,又可有效覆盖全行业用水过程的碳减排。“低碳水务”可通过新技术的应用降低单位用电量和药剂投加量,从而减少额外能量和碳源的输入,同时依靠厂区内新能源的使用、副产物能源转化等方式实现供排水行业“碳中和”目标。

3.2 实现Water industry“碳中和”的关键是管理策略与技术创新

(1)明确阶段发展目标,提高从业人员对Water industry实现“碳中和”的共识。

Water industry实现“碳中和”不是一蹴而就的,既要避免运动式的“碳冲锋”,也要避免全行业从业者对实现“碳中和”的“事不关己”。需要明确阶段性发展目标,优先减少厂区能耗、物耗,结合技术创新、工艺改良实现“碳达峰”,再进一步通过引入新能源、降低单位水处理Carbon emissions过渡至“碳中和”。通过阶段性目标的设立及从业人员培训,逐步提高Water industry工作人员对实现“碳中和”必要性、紧迫性的认识,自上而下与自下而上同步提高全行业探索节能减排技术与管理措施及积极性。

(2) Research and development of low-carbon disposal technologies to promote industrial transformation and upgrading.

进一步研发净水处理、污水处置过程中的新技术、新设备,提高处理运行效率、减少能耗与药耗、增加能源回收利用比例,积极开发包括太阳能、风能等适用于Water industry的可再生能源,推动工艺过程无人化、处理装置智能化,实现Water industry处理厂稳定运行、节约外能输入、资源再利用,使相关处理过程由能源消耗型转化为能源外溢型,实现“碳中和”运行,促进包括温室气体减排技术在内的研发与应用。

(3) Carry out full life cycle assessment to promote carbon emission reduction in the entire industry chain.

全生命周期评价有助于清晰量化各流程中物质流动时Carbon emissions情况,分析碳足迹,评估不同流程、不同技术下厂区温室气体排放潜能。应进一步健全Water industry全链条产品生命周期评价,实现“水源-净水处置-终端用水-污水处置-排水”全过程Carbon emissions评价,为开发绿色低碳水务产品、进一步降低Water industryCarbon emissions提供支撑。