Toyota's high-profile official announcement of the mass production time of solid-state battery models, have Chinese companies fallen behind?

Interface News Reporter | Banker key

Interface News Editor | Zhang Hui

Toyota, the world's largest automaker, is expected to reduce the production cost of solid-state batteries to the level of existing liquid batteries after announcing a major breakthrough in solid-state battery technology.

On July 4, the Financial Times quoted Keiji Kaita, president of Toyota's carbon neutral R&D center, as saying.

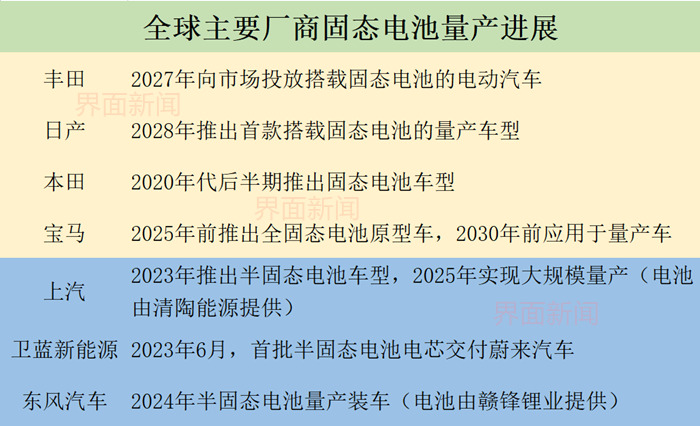

Toyota is a global leader in solid-state battery technology research and development, with more than 1,000 related patents.A month ago, the company announced its latest plans for the commercialization of solid-state batteries. As early as 2027, Toyota will introduce electric vehicles equipped with solid-state batteries that can travel about 1,200 kilometers in less than 10 minutes on a charge.

Japanese automakers Nissan and Honda have also announced plans for solid-state batteries. Nissan plans to launch its first production model with a solid-state battery in 2028. Honda plans to launch an experimental production line for solid-state batteries in 2024, and the batteries produced will be used in models launched in the second half of the 2020s, with an investment of 43 billion yen (about 2.1 billion yuan).

Electric vehicles with long range, high safety, and fast charging are the goals pursued by the industry. Compared to liquid batteries, solid-state batteries offer higher safety, longer range, and fast charging capabilities.

As a result, solid-state batteries are considered the ultimate solution to achieve that goal, and Honda has even called this technology a "game-changer" for electric vehicles.

Solid-state batteries and liquid batteries are both branches of lithium batteries, and the main difference is the use of electrolytes, which use solid and liquid electrolyte materials, respectively.

Liquid electrolytes are mainly composed of organic solvents, which can cause fire and explosion hazards if leaked to the outside of the battery, so conventional power batteries must be sturdy and use large containers to prevent electrolyte leakage.

All-solid-state batteries are exempt from this restriction, and the form of the power battery can be thinner and more compact. On the basis of reducing the risk of battery fire and explosion, all-solid-state batteries can choose higher capacity cathode and anode materials, which is expected to increase the energy density of power batteries to more than 500 Wh/kg, nearly double the current level.

At present, the range of electric vehicles using traditional liquid batteries is usually about 500 kilometers, and the range of some electric vehicles is also claimed to be more than 1,000 kilometers by using battery structure innovation methods such as CTP.

At the same time, all-solid-state batteries can also work safely in high-temperature environments, and will not deteriorate and decay under high-load charging methods such as fast charging.

In order to increase the charging speed, various battery companies are developing fast charging technology. In May this year, Sunwoda (300207.SZ) announced that its research and development of flash rechargeable batteries can support electric vehicles with an easy range of 1,000 kilometers, which can be charged from 20% to 80% in 10 minutes. On June 10, Wu Kai, chief scientist of CATL (300750.SZ), said at the World Power Battery Conference that the fast charging effect of a model of a CATL customer will reach less than 10 minutes of charging and a range of more than 400 kilometers.

In the same charging time, the range of Sunwoda and CATL liquid batteries is not as good as Toyota's planned solid-state batteries.

Compared with foreign companies such as Japan that have made high-profile mass production schedules for solid-state battery models, Chinese companies have taken semi-solid-state batteries as an entry point to realize the commercialization of solid-state batteries.At present, most of the announced progress is focused on semi-solid-state batteries.

includeQingtao Energy, Weilan New Energyand other start-ups are among the representatives, all of which have entered the countdown to mass production and loading.

Li Hong, chief scientist and founder of Weilan New Energy, has publicly stated this year that China's lithium battery will achieve technological progress from 1.0 to 4.0, 1.0 is the early mixed solid-liquid products, 2.0 is close to quasi-solid, 3.0 is the beginning of all-solid-state products, and 4.0 will be an all-solid-state solution that fully meets various applications.

Earlier this month, Weilan New Energy delivered the first batch of semi-solid-state battery cells to NIO, with an energy density of 360 Wh/kg. Batteries usually adopt the assembly mode of cell-module-battery pack, and the battery cell is the smallest unit that makes up the battery pack. Li Hong previously revealed that the semi-solid-state battery cooperated with NIO can achieve a range of 1,000 kilometers on a single charge.

Qingtao Energy disclosed at the beginning of this year that the semi-solid-state battery developed in cooperation with SAIC will be applied to the new model of SAIC's own brand within the year, with a range of more than 1,000 kilometers, and plans to achieve large-scale mass production in 2025.

SAIC Motor also recently announced that it plans to invest no more than 2.7 billion yuan in Qingtao Energy, and its shareholding ratio will increase from the current 4.2% to 15.29%, which is enough to show its emphasis on semi-solid-state battery technology.

LG Energy Solution also plans to commercialize semi-solid-state batteries in 2026, and the South Korean company is the world's second-largest producer of power batteries. But for the prospects of solid-state batteries, its main competitor CATL is not optimistic.

In March this year, Zeng Yuqun, chairman of CATL, said at the results conference that there are still many scientific and technical basic problems of all-solid-state and semi-solid-state batteries that have not yet been solved, and the company has been deeply cultivated for more than ten years, and still believes that it is difficult to form products with technical feasibility and market competitiveness.

So far, CATL has not announced a timetable for mass production of all-solid-state or semi-solid-state batteries. However, European and American car companies and emerging battery companies are still keen on the research and development of all-solid-state batteries.From the perspective of various plans, Toyota is the most advanced.

For their European and American counterparts, which lag behind Asian companies in the field of power batteries, they hope that all-solid-state battery technology will become a possible path for them to overtake in corners. At present, the world's top ten power battery companies are from China, Japan and South Korea, of which China occupies six.

As early as 2021, the BMW Group invested US$130 million (about 940 million yuan) in Solid Power, a US solid-state battery company, for the research and development of all-solid-state battery technology. According to the plan at that time, the BMW Group planned to launch a prototype car with an all-solid-state battery by 2025 and apply the technology to a production car by 2030.

In February, the BMW Group and Solid Power deepened their cooperation to build a prototype production line for all-solid-state batteries at their headquarters in Germany. The latter is clearly scheduled to deliver full-scale automotive cells for testing within the year, helping the BMW Group achieve its short-term goal of launching an all-solid-state battery prototype by 2025.

Another well-known car company, Volkswagen Group, has invested hundreds of millions of dollars in QuantumScape, another American solid-state battery company. At the end of last year, the latter announced that it had provided samples of all-solid-state batteries to car company customers, which is close to full-size automotive cells and can be used for testing mass production cars. QuantumScape did not disclose the name of the customer, although speculation is rife that it is likely to be Volkswagen Group.

Chinese companies mostly choose semi-solid-state batteries, mainly believing that this is a relatively realistic path at present. Although solid-state batteries have near-perfect prospects, the related technology research and development is not an easy road.

All-solid-state batteries were initially expected to be used in pure electric vehicles in the first half of the 2020s, but the pace of development has been much slower than expected. Toyota had planned to mass-produce hybrid models equipped with all-solid-state batteries by 2025, but this plan is no longer mentioned.

固态电解质的开发是难点之一。其主要技术方向include氧化物、聚合物与硫化物三种,目前业界还未能寻觅到兼顾综合电化学性能和生产成本的材料。

The viability of solid-state batteries moving from the lab to mass production is also a major challenge. As a result, developing all-solid-state battery technology is also known as a difficult challenge to find a destination in unexplored land.

Jagdeep Singh, CEO of QuantumScape, has also said that there is still a long way to go before the commercialization of all-solid-state battery technology. According to QuantumScape's assessment, the company does not plan to deliver mass-production-ready all-solid-state battery prototypes by 2025.

This is where the semi-solid-state battery comes into being, as a transitional product. Compared with all-solid-state batteries that use solid-state electrolytes, it still uses a certain percentage of liquid electrolyte, which is believed to combine the characteristics of easy mass production of liquid batteries and high safety of solid-state batteries.

However, the industry has different attitudes towards the commercialization prospects of semi-solid-state batteries, and there is a view that compared with traditional lithium batteries, semi-solid-state batteries have limited improvements in safety and other aspects.