What are the pain points of the low-carbon transformation of Shanxi's iron and steel industry?

"Shanxi Province plans to increase the proportion of short-process steelmaking to more than 5% by 2025. It's only a 5% increase, but it's a reality. In addition, Shanxi Province is also a national coke production base, and will gradually become the last province in the country to withdraw from coking after 2050. Recently, at the international exchange meeting on carbon emission reduction in the steel industry jointly organized by the international non-governmental organization Steel Watch, Asia Climate Activists and Energy Associated Press, Kou Jingna, associate professor of the School of Economics and Management of Taiyuan University of Technology, believes that under the "double carbon" goal, Shanxi Province is comprehensively promoting the low-carbon transformation of the steel and coking industry, but faces multiple challenges.

The high carbon emission attribute of China's steel industry is highlighted

China is the world's center of steel production and consumption. Since 1996, when crude steel output exceeded 100 million tons, China's steel output has ranked first in the world for 26 consecutive years. In 2022, the country produced a total of 1.018 billion tons of crude steel, accounting for 54.0% of the global total.

As one of the major steel producing provinces in China, the steel industry in Shanxi Province has developed steadily in recent years. In 2021, the province's pig iron, crude steel, and steel output will be 59.884 million tons, 67.407 million tons, and 61.739 million tons, respectively, ranking fifth in the country's provincial steel production.

However, at present, most of the crude steel production in Shanxi Province adopts the long-process steelmaking process. According to reports, in 2022, its crude steel output will be 64.23 million tons, with long-process steel accounting for more than 95%.

Long-process steelmaking starts from iron ore and raw coal, and goes through multiple processes to make steel. Blast furnace and converter are its key equipment. Correspondingly, short-process steelmaking refers to the production of steel with scrap as the main raw material. The electric arc furnace is its key equipment. The amount of CO2 emitted during long-process steelmaking is much greater than the carbon emissions of short-process processes. The blast furnace process of long-process steelmaking is the most important carbon emission link, accounting for 73% of the total carbon emissions.

According to data released by the National Bureau of Statistics, China's steel industry has accounted for more than 16% of the country's carbon emissions. worldsteel estimates that an average of 2.32 tonnes of CO2 is emitted for every tonne of steel produced. worldsteel reported that in 2021, blast furnace and converter processes produced up to 3.2 Gt of carbon dioxide, accounting for an estimated 86% of the steel industry's annual global greenhouse gas emissions.

As a result, panelists argued that blast furnaces determine the steelmaking industry's dependence on coal, exacerbating emissions across the entire value chain. So, can China's steel industry get rid of its dependence on coal?

The low-carbon transformation of Shanxi's steel and coking industry is facing challenges

According to experts, Shanxi Province's crude steel output is currently at a peak plateau, and the future output will enter a decline range, which is expected to drop to 56.6 million tons in 2030. Under the "dual carbon" goal, the long-process steel in Shanxi Province has been continuously reduced, and the proportion of short-process steel production has gradually increased. By 2025, the proportion of short-process steelmaking will increase to more than 5%.

On December 31, 2020, the Ministry of Industry and Information Technology issued the "Guiding Opinions on Promoting the High-quality Development of the Iron and Steel Industry (Draft for Comments)", requiring that by 2025, the proportion of China's electric furnace steel output will increase to more than 15%, and strive to reach 20%. Judging from the data, although the proportion of Shanxi Province's plan to increase by 2025 is only 5%, it is necessary to comprehensively consider the situation of Shanxi Province.

At present, only TISCO Group uses short-process electric arc furnace steelmaking in Shanxi Province. In the short term, it is unrealistic to vigorously promote the transformation of electric furnace steel and increase the proportion of electric furnace steel, which can only promote enterprises with technical foundation to increase the proportion of electric arc furnace smelting process.

"The low-carbon transformation of Shanxi's steel and coking industries faces multiple challenges. At the industry level, the main challenge is the shrinking downstream demand and the high risk of stranded assets; The industry concentration is low, the bargaining power is weak, and it is not conducive to the large-scale production of chemical products; The synergistic effect of production, education and research is weak, and it is difficult to implement innovative technologies; The regional economic and social contribution is high, and it is difficult to reduce and exit in the future; The comprehensive utilization efficiency of resources is low, and the construction of scrap steel processing and distribution system needs to be improved. At the enterprise level, coke oven gas combustion is the main source of carbon emissions, and there is a relative lack of clean alternative technology paths. There are many pollutant discharge links in the steel and coking industries, and environmental governance is difficult; The extension of the industrial chain is insufficient, and the problem of low-end products is prominent; There is a large funding gap for energy-saving renovation and a heavy financial burden; The level of fine management of enterprises is insufficient, and the professional ability needs to be improved. ”

The development status of the iron and steel industry in Shanxi Province. Courtesy of Kou Jingna

Wu Haibin and others from the Institute of Resources and Environmental Engineering of Shanxi University believe that the current situation of steel supply in Shanxi Province is oversupply, and the annual steel demand in the province is only more than 2,000 tons. This is due to the excessive concentration of the steel industry chain in the middle of the industrial chain, that is, the steel processing and manufacturing links, and there is a large gap in the downstream application market of the industrial chain.

In addition, the concentration of the steel industry in Shanxi Province is still at a low level compared with the national average and other major steel provinces. Among them, only Baowu TISCO has a scale of more than 10 million tons, and more than 10 enterprises have a steel production capacity of less than 2 million tons. The enterprise is small in scale, large in number, scattered in layout, does not have economies of scale, low level of science and technology, lacks competitiveness of products, and has weak ability to resist risks.

Steelmaking using renewable energy and green hydrogen, and using scrap wherever possible

Kou Jingna told reporters: "In the process of low-carbon transformation of Shanxi's steel and coking industries, there are many positive cases. Among the coking enterprises, Shanxi Coking Co., Ltd., Shanxi Meijin Energy Co., Ltd., Shanxi Xiaxin Energy Group Co., Ltd., Shanxi Pengfei Group Co., Ltd., and Shanxi Huaxin Coal Coking Industry Group Co., Ltd. have made active explorations in coke oven gas deep processing, coal tar deep processing, and diversified transformation. Hydrogen and methane gas account for a large proportion of coke oven gas. Hydrogen energy and methanol are raw materials for the development of some strategic emerging industries, and their development has become an important direction for the non-coal transformation of coking enterprises. As one of the raw materials for the preparation of carbon black and needle coke, coal tar has a broad market demand. Diversified transformation refers to the cross-industry transformation of enterprises to open up new economic growth points based on the environment and market demand, reduce or even get rid of dependence on coal, and cross-industry transformation. There are also many examples of positive transformation in steel companies. For example, Jinnan Iron and Steel explores blast furnace hydrogen metallurgy. Starting in February 2022, Jinnan Iron and Steel's blast furnace began to inject pure hydrogen to carry out the blast furnace hydrogen metallurgy carbon reduction and emission reduction project. 30 cubic meters of hydrogen per ton of iron can replace 12 kilograms of coul. According to the annual output of 6.4 million tons of molten iron, it can reduce coke consumption by 77,000 tons and carbon dioxide emissions by 240,000 tons a year. In addition, Jinnan Iron and Steel promotes the construction of a zero-carbon logistics park for hydrogen energy heavy trucks and a 'new energy + energy storage' project. ”

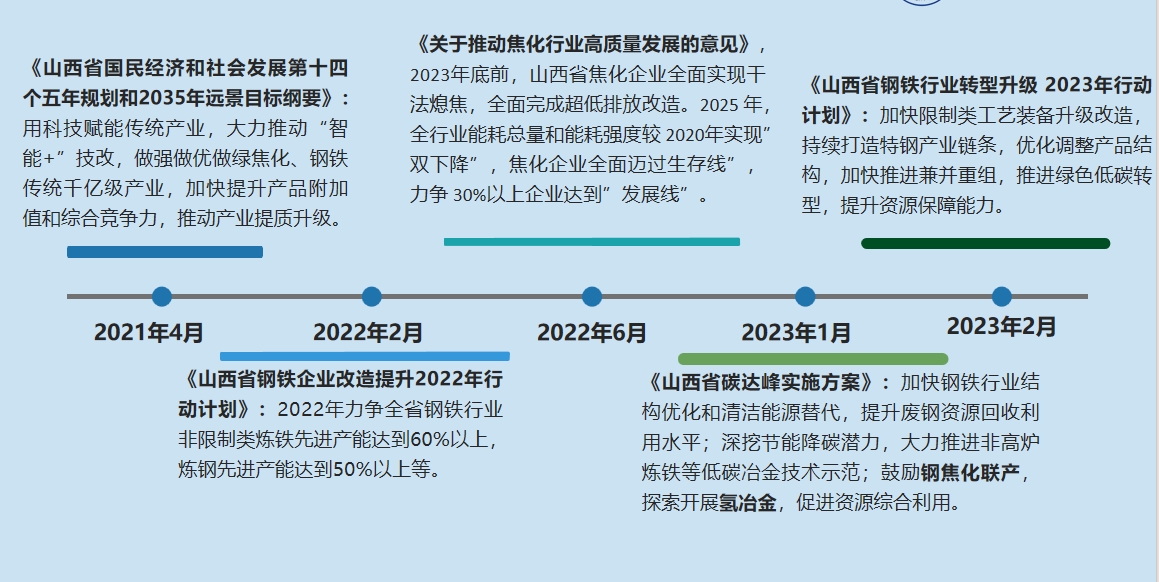

At the provincial level of Shanxi, the policy comprehensively promotes the high-quality development of the steel coking industry. Courtesy of Kou Jingna

Xiyuan Liu, the Rocky Mountain Institute's representative in Paris, said: "Steel technology needs to shift to deep decarbonisation. The current carbon emission intensity of blast furnace-converter is about 2.3 tons of carbon dioxide per ton of steel, and if green hydrogen is integrated and produced efficiently, the carbon reduction potential is about 20%-30%. The scrap-EAF process currently has a carbon intensity of around 0.4 tonnes of CO2/tonne steel, with a carbon reduction potential of 100% if converted from renewable energy. The gas-based DRI-EAF process currently has a carbon intensity of around 1.2 tonnes of CO2/tonne steel, with a carbon reduction potential of 100% if renewable energy and green hydrogen are used. The electrolytic reduction process is not yet commercially available, and the carbon reduction potential can be reached by 100% if renewable energy is used. ”

Therefore, in the future, experts believe that China's steel industry still has a lot of room for exploration in terms of green hydrogen to reduce iron ore, use clean energy to make steel, and make the greatest possible use of scrap steel.