A brief analysis of the problems exposed by some power plants in the two-year carbon emission verification

introduction

In the author's previous article, Xiaoshu talked about carbon|From the current situation of electricity carbon emissions and obvious characteristics, the impact of the carbon market that has been running for more than a year on thermal power has introduced some of the performance of the power industry after it has been included in the national carbon market.

1. Main monitoring equipment and monitoring data

Coal consumption monitoring

In the past two years of verification practice, coal burning is one of the monitoring data that has been focused on, in order to ensure the quality of the data, the monitoring equipment of the coal into the furnace has made many provisions, at present, most enterprises can use the belt scale to accurately measure the amount of coal, so after the new guidelines are issued two years after the verification practice, the amount of coal measured by the belt scale can be used as the amount of coal into the furnace, even if there is a coal feeder behind the belt scale in the process of coal-fired power generation can be used as the most accurate data.

In the past, the amount of coal used in the plant was often questioned, because the amount of coal is a data that can directly affect emissions, generally two 300,000 kilowatt power plants consume more than 2 million tons of coal per year, and the accuracy of the belt scale floats at ±0.5%, and the final deviation between the amount of coal and the actual amount of coal is ± 10,000 tons. The total impact on the final carbon emissions of enterprises is 20,000 tons.

The problem of coal consumption measured by the belt scale generally appears on the data report, and it is the most typical report-type problem, because there are many sources of coal volume data available.

Among the problems, the report does not match the actual production data, and the data table provided by the enterprise in the verification is not the same as the original record of the DCS system/business report/cumulative coal consumption/traceability, and the reason for the problem may be:

1. Measure the coal loading cycle, some of which may be coal from 10 o'clock at night to 2 o'clock the next day, and all coal during the period will be counted in the next day;

2. Internal requirements of enterprises, some enterprises may require the incoming coal and consumption to be completely consistent to achieve a balance because of the need to publish data, but in the process, whether it is the loss of moisture or the general consumption can not be completely balanced, so there will be a situation where the production report is depressed or the amount of coal is overreported.

The general way of enterprise correction is to look for a report or the most original record that can reflect the real amount of coal, but if you still use this report when reporting data, it will increase the workload of grassroots staff, coupled with the existence of inertia of enterprise reporting data, in the monthly report will still be filled in accordance with the data selection method before correction.

Fuel consumption monitoring

At present, the way to measure the amount of fuel is a flow meter or a level gauge, and the two characteristics of fuel volume because of its relatively small use and relatively small emissions have not been paid attention to in the past verification practice, and it is often the report provided by the enterprise that can be directly accepted. Quantitatively, the carbon dioxide emissions of general fuel oil are about 1,000 tons/year, while the total carbon dioxide emissions are about 1 million tons.

Due to the characteristics of verification, the measurement problem of fuel quantity is not reflected in the data, but more when filling in the measurement method, the filling personnel mistakenly make the flowmeter/level gauge wrong, resulting in the error of the data quality control plan. The general rectification plan is to propose a way to modify the measurement.

Electricity monitoring

From the point of view of the data, the possibility of data error is 0, the data can be checked in the power supply bureau, and from the perspective of monitoring equipment, the main first-level gate meter verification will be operated by the power supply bureau or special personnel, and then signed.

The problem that often arises is that the calculation of power supply is inaccurate, and the problem is reflected in the inability to accurately distinguish the power consumption of the plant (because in the metering and monitoring practice in 2023, there is no need for power supply metering, so the author does not have much space to describe the problem), each power plant in the calculation of its own plant electricity consumption even after two years of verification and correction, still presents a variety of errors and omissions, so in the new guide, the calculation of power supply is simply canceled to facilitate the filling of each unit.

Thermal monitoring

The measurement of heat is usually carried out directly by the meter and measured by the mode of flow rate and enthalpy, which is a great test of the accuracy of the meter.

The author has encountered a situation where the heat meter is incomplete, and the heat supply meter is measured by estimation when the heat meter is purchased by the buyer, and the total heat supply is measured by accurate measurement + estimation, but because the existence of the settlement voucher and the addition of the situation is an individual case, it is not questioned by the credibility.

In addition, the heat measurement method of some plants adopts the temperature and pressure of the design value, and when the supplied steam cannot reach the design value, there is an abnormal situation of heating coal consumption.

For these existing problems, there is no better selection and correction of existing data, only to remind enterprises to pay attention to the reliability and accuracy of the meter, to check the leakage and installation of the missing meter, and to actively and accurately measure under the premise that the current verification is more to provide the enterprise with a rectification direction, so as to avoid the loss caused by the upgrade of the verification rigority.

Laboratory monitoring equipment

Laboratory data and equipment are the key to check, and they are also the data with the most errors.

From the data point of view, there are various reasons for the difference between the hand-copied records, the data provided, and the data of the laboratory equipment system, such as the confusion of the records, the wrong date, etc. For this kind of problem, it is only necessary to find the original record and solve it.

The most common problem is the lack of verification, where the data measured during the life cycle of the lack of verification is penalized for accuracy and there is no way to correct it. Equipment qualification applies to all equipment except laboratory equipment.

Summary: The above key data issues should be paid attention to by all enterprises, and they should be measured as accurately as possible. For the verification work, it is necessary to improve the ability to identify data, the data provided by the enterprise is complicated, and the time given by each factory is not long, and the average time to enter the factory is about one day, which is a great test of the professional ability of the inspectors; For enterprises, how to better improve the credibility of monitoring work should be the focus of future work, and digital measurement methods, rigorous management systems, and work plans will be the mainstream direction in the future.

2. Management system

Failure to implement in accordance with regulations, and outdated management systems.

The problems in the enterprise management system mainly lie in the lack of system or outdated management system, the lack of internal audit system for data, the lack of laboratory management system, the lack of sampling and preparation plan and other deficiencies that do not meet the integrity requirements of the quality control plan; The management system is vague, the division of rights and responsibilities is not clear, the relevant personnel are not mentioned, and the organizational structure is not clear, which does not meet the content requirements of the division of the quality control plan.

3. Document integrity

The file integrity problem is aimed at all documents, which generally occurs in the data recording department, such as the loss of laboratory data due to the replacement of new equipment, and the deletion of past data due to the small memory of the laboratory computer; The management of the department for the preservation of documents is chaotic, and the saved documents cannot be provided during the temporary document inspection; The data records are chaotic, and there is a situation where one data record book is not used up, and another record book is directly used, and the record book provided is incomplete, which may be determined to be a lack of records and the data is unqualified.

4. Summary

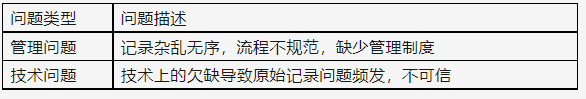

The data problems of most power plants can be summarized into two categories: one is the management problem, the lack of good institutional constraints, which leads to all kinds of disorderly records; The second is the technical problem, the lack of new monitoring and reporting methods to increase the credibility of data, and the traditional recording methods are easy to be tampered with and lose credibility in the process of reporting and tabulation.

For the relevant national authorities, new measurement methods should be explored to improve the low credibility problems identified in the existing verification process, such as multi-sectoral joint monitoring and access of laboratory system data to official databases; The online platform develops and applies to directly collect data from monitoring equipment, etc., and at the same time encourages the implementation of new monitoring methods and monitoring equipment, and improves and provides recognition.

Special note: The above content comes from the author's observation experience in the past two years of participating in the verification of enterprises, and a large proportion of the projects involved have these problems, and the picture content such as the specific report of the problem cannot be displayed due to privacy.